![]()

![]()

![]()

Paul J. Montgomery, Jr. - pjm337@psu.edu

Department of Mechanical Engineering

The Pennsylvania State University

University Park, PA 16802

Dr. Steven L. Garrett - sxg185@psu.edu

Graduate Department of Acoustics

The Pennsylvania State University

University Park, PA 16804

Popular version of paper 2pPA8

Presented Tuesday Afternoon, November 16, 2010

2nd Pan-American/Iberian Meeting on Acoustics, Cancun, Mexico

“If user demand were the sole driver of innovation, the biomass cooking stove would be one of the most sophisticated devices in the world.”

What is one of the three most dangerous activities for a woman in the developing world? Unfortunately, for nearly one-half the world’s population, the answer to this question is cooking a meal for her family. Exposure to smoke from traditional cookstoves causes 1.9 million premature deaths annually, with women and young children most affected by pneumonia and chronic obstructive pulmonary disease. Last month, Secretary of State Hillary Clinton made a speech in New York City launching the United Nations Foundation’s Alliance for Clean Cookstoves. She discusses the many problems with today's biomass burning cook stoves, as well as the possibility of using of using cook stove waste heat for electrical co-generation.

Although the health effects of indoor air pollution have been recognized for decades, it is only recently that the products of incomplete combustion, such as black carbon (soot), were also recognized as significant contributors to global warming. In many regions of South-East Asia, India, and sub-Saharan Africa, the soot generated by inefficient biomass combustion is a larger contributor to global warming than the production of carbon dioxide from those regions and when the soot falls on glaciers, it accelerates their melting as well. Unlike the CO2 that remains in the Earth’s atmosphere for centuries, black carbon has an atmospheric lifetime that is about ten days. This makes reduction in cook stove emissions an attractive target for delaying the effects of global warming while technological solutions that can reduce CO2 emissions are developed and deployed. That’s the good news. The bad news is that there are a half-billion stoves in use, mostly in locations that are not currently serviced by the commercial sector.

Recent research has shown that fan-enhanced convection in the biomass

combustion chamber makes the most significant reduction in the products of

incomplete combustion that degrades indoor air quality. The fan also reduces

fuel consumption and cooking times. Unfortunately, over half of the stove

users live in areas with no electrical services that could be used to power a

fan that requires as little as one watt of electrical power for

operation. On the other hand, a typical single-burner biomass-burning

cook stove produces between 4 and 8 kilowatts of thermal power (heat), so even

a relatively inefficient heat engine would be capable of generating enough

electricity from small amounts of waste heat to power a fan and possibly have

sufficient excess capacity to charge a cell ‘phone or a battery that

could provide lighting at night.

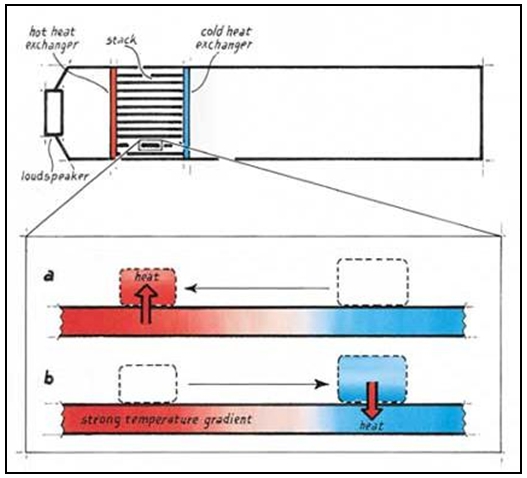

Thermoacoustics seems like a potential candidate for low-cost electrical power generation because it is so simple and requires no moving parts other than the loudspeaker which must reciprocate to generate electrical power. A simple diagram of the thermoacoustic process is shown schematically in Fig. 1.

Figure 1. Schematic showing the heat transferred between the air and the stack material in a thermoacoustic resonator. In this diagram the amplitude of a sound wave is amplified by oscillation of a gas within a resonator. A temperature difference is imposed across a porous ceramic material we call the “stack”. When the gas moves to the left it is compressed but it also picks up some heat from the ceramic, raising the pressure further. On the other half of the cycle, the gas expands and cools, but finds itself over a portion of the stack that is colder, thus reducing its pressure further. As first recognized by Lord Rayleigh, when heat is added during compression and removed during expansion, the amplitude of the oscillation will increase. The increase in amplitude caused by the heat is extracted as electrical power from the loudspeaker.

The purpose of the research we are reporting was to use a small amount of waste heat from such a stove to generate electricity by producing a high-amplitude sound wave in a resonator (so the sound does not bother the user) and use the sound to oscillate the cone of an inexpensive loudspeaker that is operating “backwards”. Instead of providing electricity to the speaker to produce sound, as you would with your radio, the sound produced by thermoacoustic processes (see Fig. 1) uses heat to create the pressure oscillations that drive the loudspeaker’s motion. The speaker’s reciprocating motion generates electrical power.

The design and fabrication of a low-cost thermoacoustic power generator presented many challenges. Although a very high-tech thermoacoustic generator has been built for space applications, it employed pressurized helium gas and a very expensive linear alternators (i.e., a loudspeaker operating “backwards”). For the cook stove application, we attempted a much simpler thermoacoustic prototype to determine the feasibility of thermoacoustic co-generation.

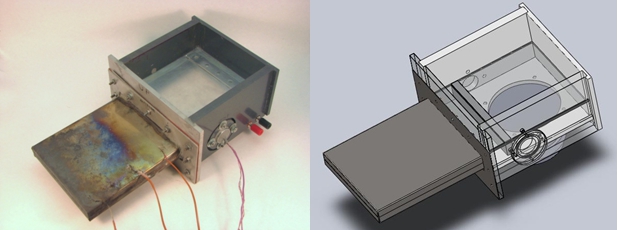

Figure 2. Thermoacoustic engine prototype assembly pictured (left) next to SolidWorks™ model (right). The overall length of the apparatus is about 25 cm. The upper wall of the SolidWorks model was made transparent to show the inside of the ambient temperature duct that reveals the exhaust heat exchanger fins and the mounting hole for the loudspeaker. Left to right: stainless steel hot-duct, flange, ambient temperature duct below the ice bath.

By using air at atmospheric pressure, we were able to build the hot-duct of the resonator from folded sheet steel that has a rectangular cross-section instead of the circular cross-section typical of vessels designed to contain gases at higher pressures (like the propane tank in your barbeque). The rectangular cross section meant that the ceramic “stack” could also have a large-aspect rectangular cross-section (i.e., very wide, but not too tall) so that the heat leaving the engine would not have to travel very far to reach ambient temperature. This made the ambient heat exchanger simple but efficient - we used the same cooling fins that cool computer chips. The exhaust heat collected by the fins was measured by determining the rate at which ice melted in the “pool” above the ambient temperature portion of the resonator.

Unlike the diagram in Fig. 1, we placed the loudspeaker at the ambient end of the resonator and utilized its moving mass, in conjunction with the gas stiffness in the hot-duct, to create a Helmholtz-like resonator that was more compact than a standing-wave resonator operating at the same frequency. We were able to eliminate the hot heat exchanger altogether. By coating the hot-end of the ceramic stack with carbon black from a candle, we were able to collect about 20 watts of heat directly by electromagnetic radiation.

Although the overall efficiency of thermal to electrical power conversion was fairly poor in this prototype, and only 25 mW of useful electrical power was extracted, it has proven that several of our innovations were workable. We plan to produce a dual-stack push-pull version that should be more efficient, since the loudspeaker will be driven by opposite pressure oscillation on the front and rear of its cone. Based on what this prototype has taught us, we should be able to reduce other losses that limit our electrical power generation capacity.

We are most grateful for the support provided by the Paul S. Veneklasen Foundation which was our sole financial resource for this effort.

1-The Economist Technology Quarterly, 389 (8609), pp.

3-4 (6 Dec 2008).

2-The UN Foundation’s Global Alliance for Clean Cookstoves; www.cleancookstoves.org.

4-V. Ramanathan and G. Carmichael, “Global and regional climate changes due to black carbon”, Nature Geoscience 1, 221-227 (2008).

5-S.L. Garrett and S. Backhaus, “The Power of Sound,” American Scientist, pp 516-525 (2000); Le son transformé en froid, Pour la Science (French-language version of Scientific American), Dossier N° 32, 112-117 (Juil/Oct 2001).

6-J. W. Strutt (Lord Rayleigh), The Theory of Sound, Vol. II (Macmillian Co., 1896; reprinted Dover, 1945), §322.

7-S. Backhaus, E. Tward, and M. Petach, "Traveling-wave thermoacoustic electric generator," Applied Physics Letters 85, 1085-1087 (2004).