Han Wang – han.wang04@gmail.com

Sungman Kim – drmanssam@gmail.com

Department of Electrical and Computer Engineering

Texas A&M University, USA

Chiwan Koo – cwankoo@gmail.com

Department of Biomedical Engineering

Texas A&M University, USA

Younghak Cho – yhcho@seoultech.ac.kr

Department of Mechanical System Design Engineering

Seoul National University of Science and Technology, Korea

Yong-Joe Kim – joekim@tamu.edu

Department of Mechanical Engineering

Texas A&M University, USA

Arum Han – arum.han@ece.tamu.edu

Department of Electrical and Computer Engineering

Department of Biomedical Engineering

Texas A&M University, USA

Popular version of paper 1aPAa2

Presented Monday morning, June 3, 2013

ICA 2013 Montreal

In large-scale oil spills, chemical dispersants are commonly used to break down oil slicks into small oil droplets so that they can quickly disperse in the vast ocean. Monitoring and studying the environmental impact of these dispersed oil droplets are very difficult because of the extremely low concentration and small droplet size (sub 100 microns in diameter). Thus technologies that can detect and accurately quantify these dispersed oil droplets rapidly and at low cost in the field will broaden applications in environmental monitoring, including oil spill monitoring in the ocean and oil leakage monitoring in water and soil. Measuring the fluorescent property of oil content in water samples through optical detection is the current standard method. However, this method requires expensive and bulky equipment, limiting its wide deployment in the field.

Here we present for the first time the development of a continuous-flow, low-concentration oil droplet quantification and separation system utilizing sound waves. When a sound wave is applied to a rectangular fluidic channel at a wavelength twice the size of the channel width, an acoustic standing wave is created inside the channel where the wave appears to be standing still. Particles under the influence of this acoustic standing wave move either to the area with low acoustic pressure (acoustic pressure node) or to the area with high acoustic pressure (acoustic pressure anti-node). The phenomenon is commonly called acoustophoresis. Whether particles move to the acoustic pressure node or anti-node and how fast they can move depends on the volume, density and compressibility of the particles and the surrounding liquid media. Oil droplets in water would experience acoustophoretic force towards the pressure anti-node in the acoustic field, which corresponds to the locations near sidewalls in a flow channel of a half-wave resonator. Our method utilizes this phenomenon to separate oil droplets from environmental water samples. Since the concentration of oil droplets in the environment is extremely small, being able to process large amounts of environmental water samples and concentrate/trap the oil droplets to a detectable level are critical for such a system to be practical. Microfabrication allows such a system to be made compact and at low-cost, enabling such a system to be field-deployable.

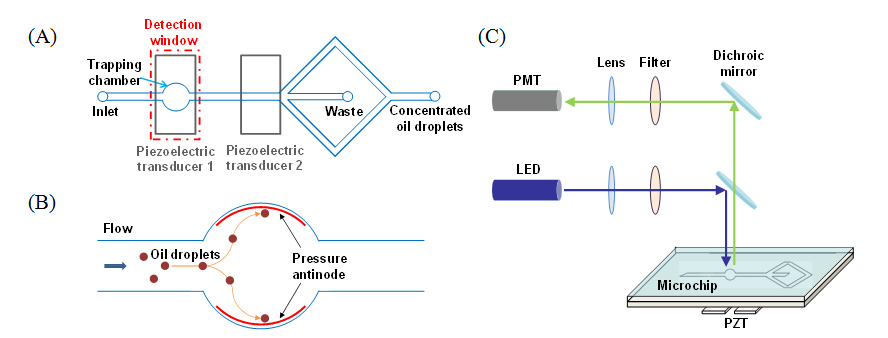

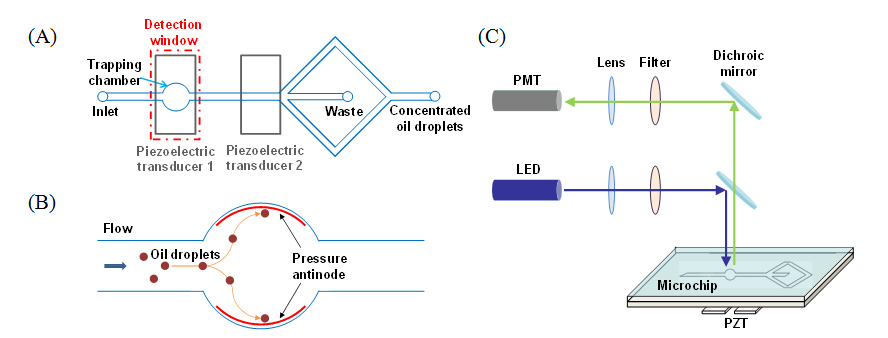

The acoustic oil droplet detection and separation system (Fig. 1A) consists of a circular trapping chamber where oil droplets would be trapped and concentrated near the sidewalls due to acoustophoretic force (Fig. 1B), and a downstream separation region with a 3-way outlet so that concentrated oil droplets once released from the trapping chamber can be separated into the side-outlets for further off-chip analysis. A compact optical detector positioned on top of the trapping region is used to detect the trapped oil droplets based on their natural fluorescence (Fig. 1C). The acoustic standing wave is created by driving a piezoelectric transducer at the resonant frequency, which converts electrical energy to mechanical vibration to form sound waves with wavelengths that equal twice the channel width. This configuration allows high-throughput concentration, detection and collection of oil droplets from environmental samples.

Fig. 1: Illustration of the oil droplet trapping, detection, and collection scheme. (A) Schematic of the microfluidic chip. (B) In a circular flow chamber, acoustic pressure antinode forms near sidewalls, thus oil droplets are trapped near sidewalls of the circular chamber. (C) Schematic of the fluorescence detection system. Oil droplets are excited with blue LED and the emitted fluorescence light is collected by a photomultiplier tube (PMT) and recorded.

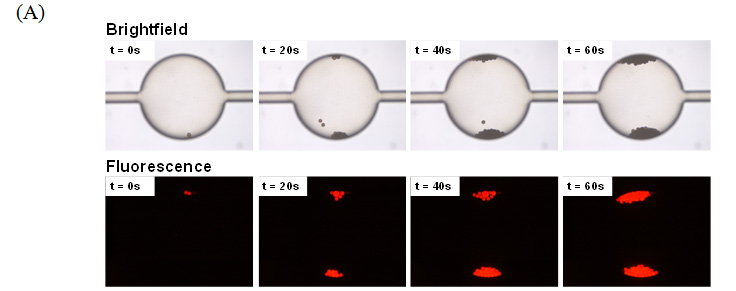

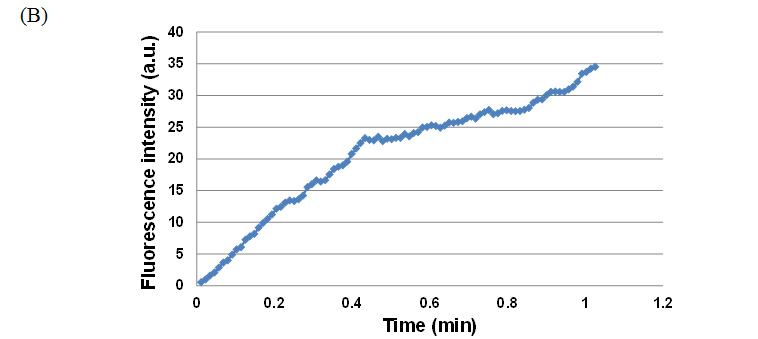

To characterize this system, crude oil droplets suspended in water with surfactant were made by a droplet generator to obtain uniformly sized droplets. Fig. 2A shows successful trapping of oil droplets from this mock sample, where oil droplets flowing through the microchannels are trapped and gradually concentrated in the circular trapping region due to the acoustic standing wave. Fig. 2B shows the fluorescence intensity reading from our custom-built compact optical detector, which increased in correspondence to oil droplet accumulation.

Fig. 2: Trapping and fluorescent detection of oil droplets (diameter: 15 µm). (A) Time series brightfield and fluorescence images showing oil droplets being trapped and concentrated in the circular trapping chamber. (B) Fluorescence signal over time as oil droplets accumulate.

In conclusion, we have successfully demonstrated for the first time the detection and separation of oil droplets from water samples using a sound wave. The continuous flow configuration allows fast processing of large quantities of environmental samples, which offers an additional benefit. This system holds promise as a portable, highly efficient, and highly sensitive on-site oil spill detector.

Acknowledgments

We would like to thank the U.S. Army Engineer Research and Development Center (ERDC) for their support (W9132T-12-2-0022). We would also like to thank the Korean Ministry of Knowledge Economy (grant 10039890) for their support.