Popular version of paper 4pPA4

Presented Thursday afternoon, December 4, 1997

134th ASA Meeting, San Diego, CA

Embargoed until December 4, 1997

Separation is an integral part of many industries, with a prominent role in everything from the manufacture of chemicals, metals, plastics, pharmaceuticals, fossil fuels, and paper, to key roles in the treatment of waste, recycling, food processing, and biotechnology. A separation process sorts materials based on differences in one or more physical properties. For example, centrifugation is commonly used to separate blood based on differences in density, while filtration is used to separate particles by size. Other common methods of separation include distillation, evaporation, and electrophoresis (separation based on electric charge differences).

Acoustophoresis is the separation of particles using high intensity

sound waves. It has long been known that high intensity standing waves

of sound can exert forces on particles. A standing wave has a pressure

profile which appears to "stand" still in time. The pressure profile in

a standing wave varies from areas of high pressure to areas of low pressure.

Standing waves are produced in acoustic resonators. Common examples of

acoustic resonators include many musical wind instruments such as organ

pipes, flutes, clarinets, and horns (see figure 1).

The force exerted on a particle by the standing wave depends partly on the strength and frequency of the acoustic wave, as well as the size of the particle. Furthermore, the force depends on the relative elastic properties of the particle and the liquid in the resonator. For example, consider a liquid containing particles which are more "compressible" than the liquid, such as an oil drop in water. When the sound field is turned on, the particles will feel a force which tends to push them to the nearest acoustic pressure maximum. If the particles were less compressible than the fluid, they would migrate towards the nearest acoustic pressure minimum.

The particles will form "bands" and may begin to sediment out of the liquid as the particles clump together. There are commercially available devices which combine an acoustic resonator with a steady flow of liquid through the cell. The particles become trapped by the acoustic field and are collected at the bottom of the resonator as they sediment out. The liquid flowing out of the resonator has most of the particles removed.

This example illustrates how particles can be separated from a liquid, but it is also possible to separate two or more different types of solid particles based on differences in their compressibilities and densities. Say, for example, that we have a liquid containing two types of particles which differ in elastic properties. One type of particle is more compressible than the liquid, while the other type is less compressible. When the liquid in the resonator is subjected to a strong acoustic standing wave, the forces on the two types of particles will be in opposite directions, causing them to separate and migrate towards distinct positions in the standing wave.

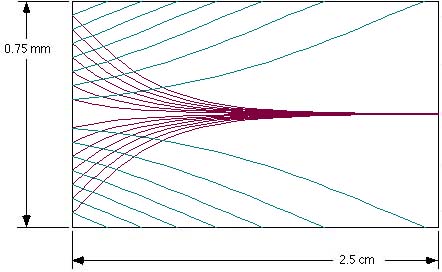

Acoustophoresis can be integrated into a continuous process, in which a steady flow of liquid is fed through the resonator such that the motion caused by the acoustic forces will be perpendicular to that of the flow. By the time the particles reach the output end of the resonator, they will be separated and the portions of the flow containing the different particle types can merely be picked off by one or more thin separators.

Because acoustophoresis separates particles based on differences in elastic properties, it is useful in separating particles similar in size, charge, and density which can not be distinguished by other processes. In optimizing a system for separating different types of particles, there are several considerations:

Here at the Yale Acoustics Laboratory, we are currently exploring several cell configurations in hopes of optimizing the separation process. Results will be presented and discussed at the talk in San Diego.

[Work supported by NASA through Grant NAG8-1351.]