Acoustical Society of America

ICA/ASA '98 Lay Language Papers

Sonic Gas Analysis

Matthew V. Golden golden@sabine.acs.psu.edu

Robert M. Keolian

Steven L. Garrett

Penn State Graduate Program in Acoustics

P.O. Box 30 State College, PA 16804

Popular version of paper 3pED4

Presented Wednesday afternoon, June 24,1998

ICA/ASA '98, Seattle, WA

Introduction

Children are always amused when an adult inhales helium gas and then speaks in a tone of voice usually reserved for cartoon characters. This increase in the pitch of the person's voice is due to the speed of sound in helium being three times greater than the speed of sound in air. Our sonic gas analyzer exploits this effect to measure the molecular weight, hence the composition, of gas mixtures by automatically, precisely and continuously measuring the sound speed. At this meeting, we report an innovative dual resonator geometry and transduction scheme, which improves analyzer response time and radiates very little sound. It employs a dipolar microphone and speaker combination, which enhances the desired signal while providing common-mode rejection of environmental noise.History

Sonic Gas Analysis was originally used in German mines before the turn of the century. This sonic gas analyzer used two whistles mounted next to one another. Gas from the mine vented through the first whistle. The composition of the mine gas determined the pitch, or frequency, of the sound emitted by the first whistle. A second whistle, mounted next the first whistle, vented outside air. As long as air was the only gas in the mine, the whistles made the same sound. If methane or hydrogen where present in the mine, the frequency of the first whistle would change. The interaction of the sounds made by the two whistles created a warbling in the loudness of the sound, known as beats. These beats warned the miners that there was a possibility of a mine explosion so they could take appropriate action to advert the disaster.Soon, other methods of gas analysis displaced sonic gas analysis due to the emergence of electrical measurement technology. The primary method that replaced sonic gas analysis was thermal conductivity gas analysis, which uses a Wheatstone bridge. The change in voltage output across the bridge indicates a change in the composition of the gas. In sonic gas analysis, a change in the composition of the gas manifests itself as a change in frequency. In the first three-quarters of this century, the precision-to-cost ratio of voltage measurements was much higher then that of frequency measurements. In addition, the transducers (speakers and microphones) used in the acoustic gas analyzer where more expensive than the heated wires used in a thermal conductivity gas analyzer. This has since changed. Now, the precision-to-cost ratio of frequency measurements is much higher then voltage measurements. As evidence of this fact, a common wristwatch, costing approximately $20, has a 5 parts per million accuracy. A voltmeter with the same accuracy would cost over $1,000. Furthermore, the cost of transducers, and commercial-off-the-shelf electronic components has come down considerably. This reversal in market forces has renewed the interest in sonic gas analysis.

Theory

Sonic gas analysis takes advantage of the fact that the speed of sound changes in different gases. The speed of sound in a gas, along with the length, determines the resonance frequency, or pitch, of a pipe or tube. The resonance frequency is the frequency at which the gas in the tube will most vigorously vibrate when driven by an external source. If the same source is used to drive, or excite, the air in the tube at a frequency other then the resonance frequency, the air will not vibrate as much. A good example of resonance is a swing. Every swing has a different resonance frequency depending on the length of the chains of the swing. With very little practice, a person can determine when to kick his/her legs to make the swing go higher and faster. The person is kicking his/her legs at the resonance frequency of the swing. The swing would not move as much if the person kicked his/her legs at another frequency. The tube used in sonic gas analysis is kept at resonance by an electronic tracking system. The electronics can also be used to determine the speed of sound of the gas in the sonic gas analyzer. The speed of sound of a gas is dependent on the molecular weight of a gas, the temperature of the gas, and the ratio of specific heats of the gas.The effect of temperature on the speed of sound is compensated electronically. The effect of the ratio of specific heats can be assumed to be negligible for most gases of interest. With the temperature and the ratio of specific heats accounted for, the average molecular weight of the gas is the primary variable affecting the speed of sound of the gasses in a sonic gas analyzer. Therefore, it is possible to determine the average molecular weight of the gas in the sonic gas analyzer.

Determining the average molecular weight of gas in the sonic gas analysis can be very important. This information may be used to determine the composition of the gas in question. For example, if you wanted to test a known gas for a certain contaminant, with a given molecular weight, you could put the gas into the sonic gas analyzer. The analyzer would then determine the molecular weight of the gas in the analyzer. Since the gas was known to begin with, the theoretical molecular weight is also known. Then with simple algebra, the amount of contaminant could be found.

Applications

There are many possible applications for the sonic gas analysis. Sonic gas analysis can be used for the same applications that thermal conductivity gas analysis can be used for. Plus, a sonic gas analyzer is rugged, rapid-response, self-calibrating, inexpensive, reliable and easy to operate, and can be very small. These are features that thermal conductivity gas analysis does not always have. Therefore, sonic gas analysis can be used for applications and in locations where thermal conductivity gas analysis can not be used. Some examples of this are: personal gas sensors for miners, and hydrogen detectors in battery compartments of boats and electric cars. Recently, there have been explosions in sewers in Mexico and Turkey, which killed hundred's due to methane build up. These disasters could be averted with sonic gas analysis.Pictures

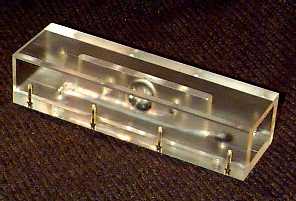

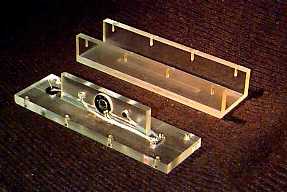

Pictures of the resonator used in sonic gas analysis.

Assembled view

Disassembled view

Contact Information

Steven Garrett and Robert Keolian can be reached for questions during the week of the meeting at The Seattle Sheraton Hotel and Towers. Tel.: (206) 621-9000