Cesare Hall - cah1003@cam.ac.uk

Cambridge University Engineering Department

Cambridge, U.K.

Popular version of paper 2pNS2

Presented Tuesday afternoon, November 16, 2004

148th ASA Meeting, San Diego, CA

What would the engines for an aircraft that is radically quieter than today's airplanes look like? Is it possible to design an engine that achieves a dramatic reduction in noise emission that also has acceptable operating costs?

The Cambridge-MIT Institute (CMI) is currently working on a research project called the Silent Aircraft Initiative. This project has a particularly bold aim: to reduce aircraft noise to the point where it would be unnoticeable in the urban areas around airports. The engines are the largest sources of noise from aircraft and therefore to meet the Silent Aircraft noise target a very new and novel engine design is required.

Take-off jet noise is the most difficult form of engine noise to reduce and therefore we will consider this first. The only sure way to reduce the exhaust jet noise is to reduce the jet speed. However, it is the difference in velocity between the jet and the surrounding air that generates thrust and if the thrust is not high enough, the aircraft cannot take-off. Thus to quieten the jet whilst maintaining thrust it is necessary to have a very large exhaust with relatively low jet velocity. In fact, for jet noise to be eliminated as a problem for the Silent Aircraft, the total exhaust area must be about three times as large as that of today's conventional jet engines.

To be economically viable, the Silent Aircraft engine needs to be low-weight, efficient and reliable. A large engine exhaust area can have a significant negative impact on all of these factors. For example, with a conventional civil transport jet engine (also known as a turbofan), if the exhaust area increases the overall engine diameter will also increase. This implies an increase in engine weight because the size of the fan components and the engine ducting rises. Variable geometry exhaust systems are required to reduce this weight increase and these are discussed later.

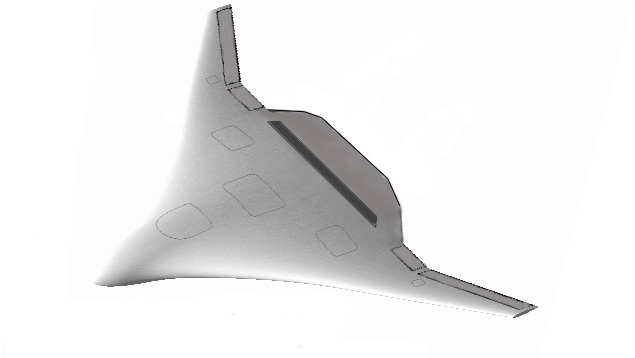

In terms of efficiency, we have to consider the fuel consumption of a quiet

engine during cruise. As the fan diameter increases and the exhaust jet velocity

reduces, the kinetic energy lost in mixing the jet with the ambient air is lowered

and as a result the so-called "propulsive efficiency" increases. However,

this effect is countered by the drag increase that results from having a larger

engine. The amount of drag contributed by the engines depends on how they are

integrated with the airframe. The Silent Aircraft airframe is expected to be

a configuration in which the wing and fuselage are merged together, as illustrated

in Figure 1. This type of aircraft has a very efficient shape that helps reduce

fuel consumption and minimise noise emission.

Figure 1: A possible airframe for the Silent Aircraft

If large, quiet engines were attached to the above aircraft using pylons and individual pods, the additional drag would be unacceptable. However, by embedding low-noise engines into the aircraft body the extra surface area exposed is much lower and therefore the overall performance should be competitive. Figure 2 summarises the options that are being considered for packaging the engines with the Silent Aircraft airframe.

Figure 2: Options considered for integration of the Silent Aircraft's engines

Embedding the engines has benefits in addition to lower fuel burn. Firstly,

the potential for noise reduction is increased because there is more space for

acoustic treatments, greater reflection of the noise away from the ground by

the airframe body and more possibility to reshape the exhaust jet. Secondly,

the airframe design is expected to improve because it will have lower weight

and improved handling. Thirdly, the scope for novel design solutions such as

variable geometry designs is increased. Furthermore, only embedded engines can

be designed to remove the low velocity airflow from the upper surface of the

airframe that is responsible for the airframe drag and noise. This approach

is called "boundary layer ingestion" and it is the same technique

that is used for the propulsion of torpedoes. If it can be successfully developed

for aircraft it has the potential to reduce fuel consumption significantly.

As indicated above, the size of the Silent Aircraft engine also has implications

for its reliability. A larger fan, with corresponding lower pressure rise, is

more susceptible to vibration problems and these problems will be worse for

an embedded system because the engine will be exposed to non-uniform airflow

from the airframe. To prevent the fan becoming unstable and thus causing engine

damage, either a very heavy over-sized engine design is needed or some variable

geometry must be introduced. Fortunately, the same variable geometry also helps

the engine change from a low noise propulsion system at low altitude to a high

efficiency system at cruise altitude. Variable geometry is therefore expected

to be a key feature of the Silent Aircraft propulsion system and three possible

options are considered here.

The first candidate engine concept for the Silent Aircraft is shown in figure

3. It is a conventional turbofan engine with the fan driven via a reduction

gearbox and a large variable exhaust nozzle. The gearbox allows a low-speed,

quiet fan to be driven by a high-speed, low-weight turbine. The variable geometry

nozzle can be opened up during take-off and approach, leading to low jet velocities

and thus low noise as well as helping the fan to stay stable. At altitude, the

nozzle is closed down to minimize fuel consumption.

Figure 3: Ducted high diameter engine with geared fan

A second option, shown in figure 4, is to have a conventional

jet engine that uses devices called "ejectors" for take-off and landing.

Ejectors are ducts outside of the engine exhaust that are used to entrain additional

air into the exhaust flow, thus reducing its overall velocity. The ejectors

can be stowed at cruise to remove their drag effect and they do not have to

be circular, which makes them more amenable to an embedded system with a variable

geometry exhaust. Overall, the use of ejectors enables a smaller and lighter

engine fan design than possible with a conventional turbofan.

The two-stage aft contra-rotating fan shown in figure 4 has been examined in

several studies that indicate this arrangement could provide further weight

and cost benefits.

Figure 4: Embedded aft contra-fan engine with ejectors

A large, low-speed jet area can also be produced by having extra fans that are only operating at take-off (figure 5). These fans can be driven by the main engine but only exposed at low altitude. Thus, their design can be optimized solely to minimize take-off and approach noise whilst the main engine could be designed to have the best possible cruise performance.

Figure 5: Optimised cruise engine with auxiliary fans for take-off

In summary, to achieve an economically viable and quiet engine for the Silent Aircraft, a variable geometry system is needed that can be effectively integrated with the airframe. Variable geometry enables the engine design to have good cruise performance as well as low jet noise at take-off, whilst embedding the engines into the airframe has several potential benefits including lower fuel consumption. There are considerable engineering challenges associated with designing and developing such engines and overcoming these will be the focus of future work.

References

[1] R. Liebeck, "Design of the blended-wing-body subsonic

transport," presented at 40th Aerospace Sciences Meeting and Exhibit, Reno,

NV, 2002.

[2] D. L. Rodriguez, "A Multidisciplinary Optimization Method for Designing

Boundary Layer Ingesting Inlets," Stanford University, Stanford, CA, USA

2001.

[3] D. L. Daggett, S. T. Brown, and R. T. Kawai, "Ultra-Efficient Engine

Diameter Study," NASA CR-2003-212309 2003.

[4] P. R. Gliebe and B. A. Janardan, "Ultra-High Bypass Engine Aeroacoustic

Study," NASA-2003-212525 2003.