148th ASA Meeting, San Diego, CA

Chemical Detection With a MEMS Microphone

Dr. Michael Pedersen- mpedersen@comcast.net

Novusonic Corp.

17942 Pond Road

Ashton, MD 20861

Popular version of paper 2aEA7

Presented Tuesday morning, November 16, 2004

148th ASA Meeting, San Diego, CA

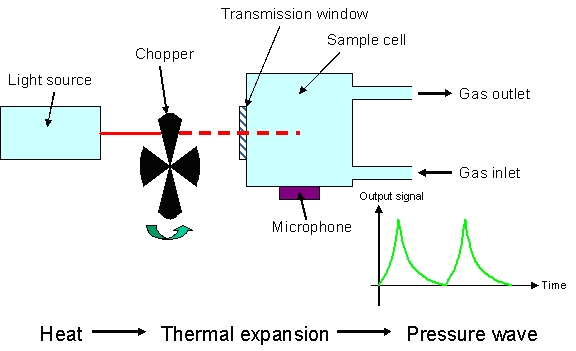

In this paper we discuss a project currently under

way to

develop a micro mechanical MEMS microphone specifically for use in

photoacoustic instruments. Photoacoustic spectroscopy (PAS), which

measures

the molecular

absorption of light energy to provide identification of molecules with

high

resolution, is a simple and promising technology for use in biochemical

sensors

and detectors.

What is

photoacoustics?

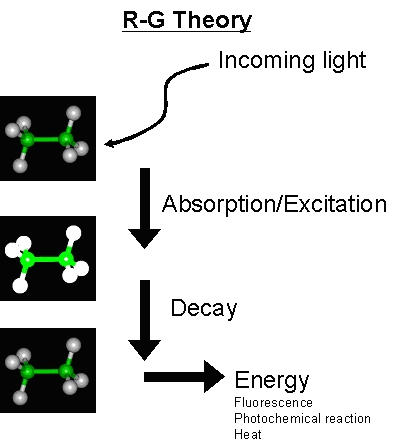

Figure 1 (upper) and 2 (lower): The original spectrophone designed by Bell and basic principle of photoacoustic conversion.

Why

use MEMS microphones for this?

High vibration sensitivity.

High cost.

The frequency range of interest in microphones for photoacoustics is from about 100Hz to a few kHz. Since the microphones currently used have bandwidths sometimes in excess of 10 kHz, a lot of potential microphone sensitivity is lost. As a result, as shown in table 1 below, it is possible to design a much smaller MEMS microphone, which still has higher sensitivity and lower thermal noise level than the measurement microphone. The vibration sensitivity of microphones is directly related to the thickness of the pressure sensing membrane inside the microphone. Conventional microphones have much thicker membranes than what can be realized in MEMS microphones. As a result, a reduction in vibration sensitivity of more than 10 times can easily be realized. The vibration sensitivity is one of the most important issues, which has largely limited photoacoustic spectroscopy to the laboratory environment where structure-born noises can be minimized. MEMS microphones will help in the realization of rugged photoacoustic field equipment, and hence help the technology compete against other detection methods in the field. The performance of a photoacoustic MEMS microphone is summarized in table 1 with the specifications of two other microphones currently used in instrumentation.

|

Table

1:

Performance

comparison of conventional microphones used for PAS and proposed MEMS

microphone. |

|||

|

|

Brüel

& Kjær 4189 Capacitive Microphone |

Knowles

EM-3446 Capacitive Microphone |

Photoacoustic MEMS microphone |

|

Diaphragm size |

~12.5mm Ø |

~3x3mm |

1x1mm |

|

Diaphragm thickness |

Unknown |

~25 micron |

0.5 micron |

|

Diaphragm

resonance frequency |

14 kHz |

5.2 kHz |

4.3 kHz |

|

Open-circuit sensitivity |

50 mV/Pa |

17.8 mV/Pa |

432 mV/Pa |

|

Frequency response |

6.3 Hz to 20 kHz ±2 dB |

300 Hz to 9 kHz ±3 dB |

10 Hz to 4 kHz ±2 dB |

|

DC bias voltage |

0 V (Internal bias) |

0 V (Internal bias) |

1.2 V |

|

Microphone capacitance |

13 pF |

~3 pF |

1.5 pF |

|

Input

referred noise level |

14.6 dB(A) SPL |

25 dB(A) SPL |

0 dB(A) SPL |

|

Maximum sound

pressure |

158 dB SPL |

Unknown |

94 dB SPL |

|

Vibration

sensitivity @ 1 g |

82.3 dB SPL |

63 dB SPL |

55 dB SPL |

|

Operating

temperature range |

-30 to 150 ºC |

-17 to 63 ºC |

-40 to 150 ºC |

|

Price |

>$200 w/o amplifier |

~$10 w/ amplifier |

~$10 w/ amplifier |