ASA/CAA '05 Meeting, Vancouver, BC

Harp Design and Construction

Chris Waltham waltham@physics.ubc.ca

Department of Physics & Astronomy

University of British Columbia

Vancouver BC, Canada V6T 1Z1

Popular version of paper 5aMU8

Presented Friday morning, May 20th, 2005

ASA/CAA '05 Meeting, Vancouver, BC

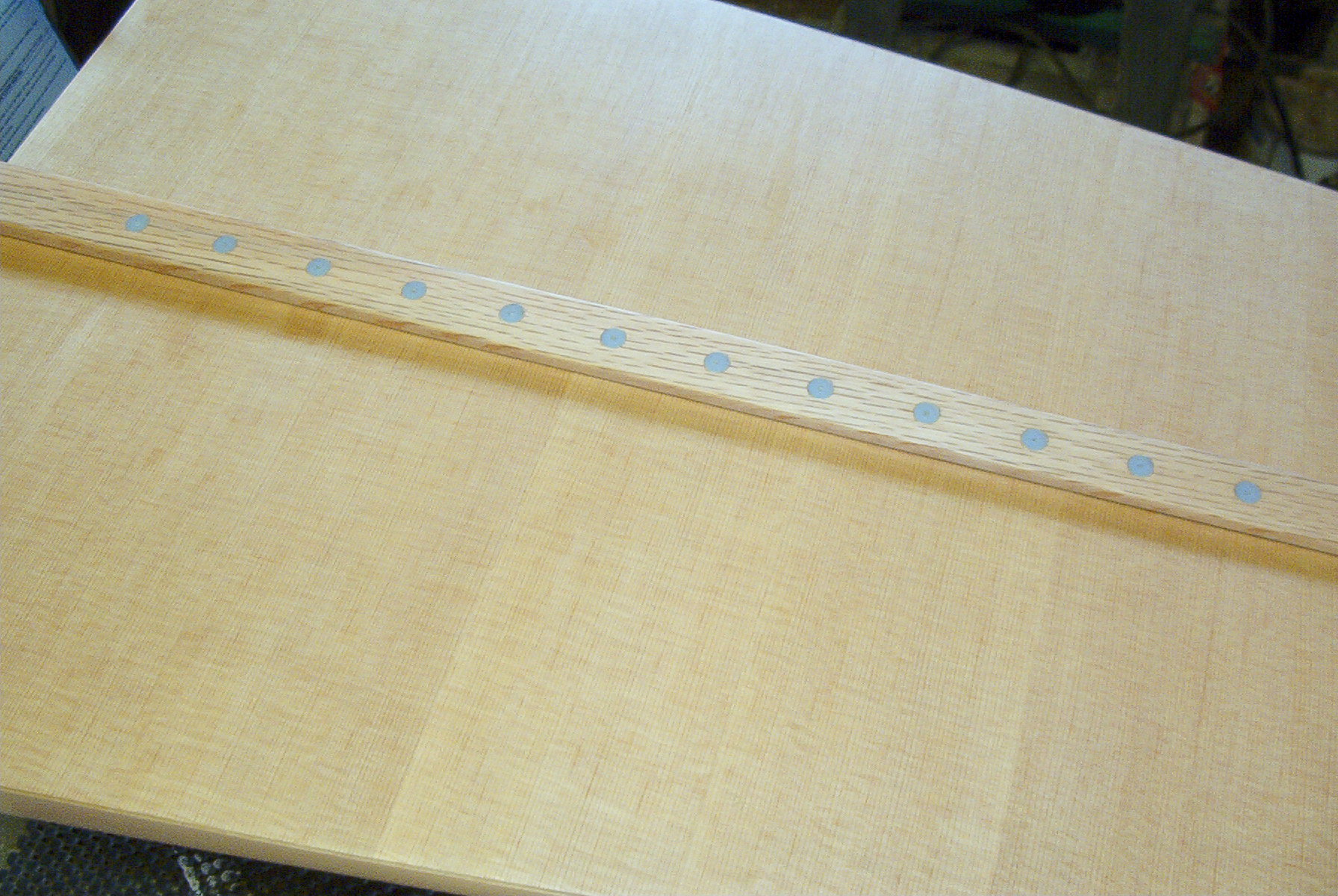

Construction

The harp is triangular in shape. The easiest part of the triangle to

make is the post (fig. 1), as it plays little part in the sound

production and

can therefore be over-engineered; the compressional force is in any

case

mostly axial. The neck has to withstand the total tension of all the

strings, and also a large torque, as all the strings are mounted on one

side. The curvature does not help, and as much of the characteristic

grace and

elegance of a harp derives from the neck shape, it cannot be overbuilt.

Very strong many-layered plywood seems to be the best material, covered

with veneer for beauty's sake. The soundboard has to be both thin

(note how floppy it is), and also to withstand all the string tension

(6000N in this case - more than half a ton). Sitka spruce is the

material of choice, for its acoustical properties and anisotropic

strength. The grain runs horizontally, and thin veneer with vertical

grain is applied to prevent

cracking (although it degrades the sound slightly). The soundbox is a

light, hollow shell, with holes at the back

for improved sound radiation and access to the strings. The whole

structure bends alarmingly under the string tension (and occasionally

explodes), so the veneer has to be very well bonded.

| Figure 1: Construction Sequence |

|||||

|

|||||

| Post capital

and base on lathe (birch) |

Mortising

the post capital |

Neck (baltic birch ply, birch/maple veneer) |

Soundboard (sitka spruce) |

Soundbox (birch/maple veneer on "rubber" ply) | String

support (oak and nylon) |

The Finished Product

In the following panel I have placed my own celtic and lever harps

in the context of harp evolution (fig. 2). The harp has been

basically

triangular-shaped for about 1000 years. The gothic harps had small,

thick soundboxes and soundboards carved out of two solid pieces of

wood, and needed "brays" to buzz against the strings and increase the

sound output. Larger, more efficient soundboards came with the celtic

harps. In the renaissance, soundboards were made ever thinner,

especially in Spain. Chromatic tuning was achieved by having two or

three rows of strings, making the harps very difficult to play, and

multiplying the total force on the soundboard. Sharpening levers to

raise the pitch of the strings by a semitone went some way to solving

this problem. The ultimate "modern" concert harp was developed by Erard

in Paris and London around 1800; these had pedals attached to a complex

mechanism which could raise the pitch of the strings by one or two

semitones.

| Figure 2: Evolution of Harps |

|||||

| Small soundbox, thick soundboard |

Larger soundbox |

2,3 string rows: chromatic |

Levers for semitone

sharpening, thin soundboard |

Double-action pedals |

|

| Gothic Harp

(C15),Hofburg Museum, Vienna |

Homemade Celtic harp (18 strings) | Arpa a tre

file (1625), Museo Civico, Bologna |

Homemade

lever harp

(36 strings), copy of George Morley model (London, 1820) |

Erard Harp c.1800 (modern concert harp), Hofburg Museum, Vienna | |

Strings

The string material is determined by harmonicity (the overtones

should sound pleasant) and "feel" (fig. 3). Harmonicity requires that

the string

be strong, heavy enough, but not stiff. "Feel" is how hard the player

has to pull to move the string centre a given amount before release; it

should be large enough that the strings do not touch, and not vary too

much from string to string. Nylon or gut would probably suffice for all

strings if the lower strings followed the curve set by the upper

strings and became very much longer than they actually are. Gut is

mechanically similar to nylon but has a warmer tone for the

mid-register. Practical reasons make the harp neck a double curve (an

ogive, so it isn't too tall) and so much heavier strings are needed for

the low register. Nylon/gut strings would have to be very thick here,

very inharmonic, and the feel would be so small that the strings would

interfere with each other. Steel wrapped with helical copper wire is

used, although there is an awkward change in feel at the break.

| Figure 3: String data measured on a

Salvi Aurora Concert Harp |

|

|

|

| Basic harp shape and position of

string types |

Maximum stress (and tension)

occurs in the steel strings |

|

|

| The highest steel and nylon

strings feel the tightest to the player |

The steel keeps the

inharmonicity low for the lowest strings |

The Characteristic Sound of a Harp

- The string is plucked in the middle, which reduces even harmonics. In some music, the harp is sometimes plucked close to the soundboard in order to imitate a guitar.

- There is very strong coupling, via to soundboard, between any two

strings with overlapping overtones. In the case of a

large harp, many strings vibrate when only one is plucked; see figs. 4

and 5.

- The long strings vibrate in collapsing and expanding ellipses,

which gives many strings a long pulsed tail to the sound (fig. 6).

- The large number of strings allows for glissandi, a feature most people

immediately associate with the harp.

Not so easy is it? Even when you hear it - without visual clues - it is not completely obvious. Look at the spaces between the overtones; the harp has many faint spikes caused by other strings starting to resonate. There is very string one at 262 Hz from the C4 string (an octave and a minor third away - a factor of about 7/3).

- String motion data taken by Gary Chan, as part of his

undergraduate thesis work; thanks to Andrzej Kotlicki for the position

sensors.

- Thanks to the UBC Music Department for the loan of the Salvi

Aurora.

- The sonogram software was obtained from www.baudline.com.

- Harp plans from Robinson Harps, California.