Noise and Energy Consumption in Heating, Ventilation and Air Conditioning Systems

Philip Sanders - PSand90@mindspring.com

San Jose, CA

Peter Rumsey

Rumsey Engineers

Oakland, CA

Popular version of paper 1pNS7

Presented Monday afternoon, October 26, 2009

158th ASA Meeting, San Antonio, TX

A group of friends enjoys a hike on a quiet, shady trail in a regional park in the Santa Cruz Mountains foothills after a hectic workweek in Silicon Valley. Its a warm Sunday afternoon. They come around a bend in the trail near the park boundary, and whats that sound? An air-conditioner, way out here in the hills?

This is one scenario city officials may have anticipated when they imposed strict noise limits for property owners building large houses adjacent to park land. It is also the challenge that led one property owner to redesign the air conditioning system for a luxury home so that it would both meet the property line noise limit and save energy.

The original air-conditioning system design included a piece of equipment big enough to cool a small office building placed 20 feet from the park boundary. With this design, meeting the citys noise limit of 40 dBA, comparable to an audible whisper, would have been virtually impossible.

After multiple meetings, during which the design team tried to design a noise reducing enclosure for the equipment, the mechanical engineer and acoustical consultant suggested using a ground source heat pump system to replace the traditional air conditioner. This involved burying hundreds of feet of pipes deep in the ground to take advantage of the constant cool temperature there, and installing a number of water source heat pumps -- small fans with compressors -- inside the house, where each one cools a small part of the house. The heat pumps transfer heat from the house to water in the pipes, which is then re-cooled as it travels through the underground pipes. Pipes buried in the ground make no noise, and the pumps required to push water through the pipes were small and quiet enough to meet the noise limit. So the noise problem was solved and the homeowner inadvertently became an early adopter of a green building technique.

This is one example of how noise reduction and energy conservation go together. Others become apparent when we look at the sources of noise in standard forced air systems.

The traditional approach to reducing noise in heating, ventilation, and air conditioning (HVAC) systems goes something like this:

1. Mechanical engineer calculates how much cooling and heating is required and designs a forced air system with all the needed components for heating and cooling, including fans, cooling towers and chillers, boilers, and ducts to deliver heated or cooled air to rooms where people live and work

2. Acoustical consultant reviews the completed design, calculates approximate noise levels in offices and conference rooms, or in bedrooms and living rooms, and recommends noise reduction measures, such as duct lining and silencers similar to mufflers to reduce noise to acceptable levels

But duct lining and silencers not only reduce noise, they also increase resistance to airflow -- just as a muffler in a car increases resistance to the flow of exhaust gases. Increased resistance to airflow means the fan has to work harder to push air through the ducts, which increases energy consumption.

There is a better way. The same factors that affect the energy a fan consumes also affect the noise it produces. The three factors that determine how much noise a fan is likely to make are:

1. Air volume - How much air does the fan have to move?

2. Static pressure - How much do the ducts, diffusers, etc. resist air flow, or how hard does the fan have to push to get air to move through the ducts?

3. Tip speed - How fast do the fan blades move?

Increasing any of these factors makes a fan louder. Reducing any of them makes a fan quieter.

In a typical forced air heating and cooling system, three factors that affect energy consumption are:

1. Heating and cooling loads - How much heat needs to be transferred into or out of a room to keep people comfortable?

2. Static Pressure - How hard does he fan have to work to move air through the ducts?

3. Fan speed - Fans that spin more slowly typically consume less energy than fans that spin faster to move the same quantity of air against the same resistance.

So to design an energy-efficient HVAC system a mechanical engineer tries to:

1. Reduce the heating and cooling load by using good insulation, dual pane windows, sunshades, fluorescent lights instead of incandescent lights, etc. Since air is the medium for moving heat in a forced air system, reducing the load reduces the total air volume that a fan has to deliver.

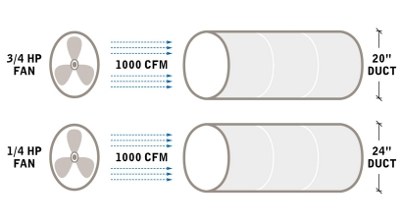

2. Maximize the sizes of the ducts. Air moving past the walls of a duct creates friction that resists airflow. The faster the air moves, the greater the resistance. Imagine blowing air through a very narrow straw, and then imagine how much easier it would be blow air through a large straw, or even a water pipe. Small ducts squeeze air, and make fans work hard.

Credit: EHDD Architects

Designing well-insulated walls windows and roofs, shading windows, and allowing adequate space for large ducts allows the mechanical engineer to select smaller fans that use less energy and generate less noise.

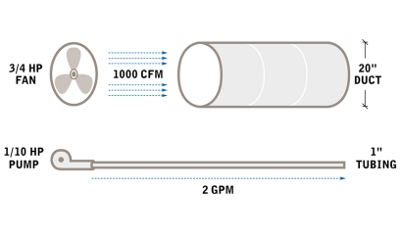

Lets take energy conservation a step further. It takes less energy to move heat from one place to another using water as a medium, than using air. So it is possible to heat or cool a room more efficiently by heating or cooling its surfaces -- floors, ceilings, possibly even walls -- than by blowing hot or cold air into it. Radiant systems move water around using electric pumps, rather than moving air around using fans. Pumps are very quiet compared to fans, and the noise they do generate is easy to attenuate with proper vibration and isolation and well-sealed doors.

Credit: EHDD Architects

Buildings with radiant heating and cooling systems still require fans to ventilate the rooms where people live and work, but the air volumes required for ventilation alone are lower than those required to heat and cool rooms. So the fans needed are smaller and quieter.

These are not new concepts, just a slightly different way of thinking about them. Many of the products and techniques that produce the dual benefits of significantly reduced noise and significantly reduced energy consumption still carry hefty cost premiums. However, an increasing number of design situations cannot meet noise requirements in any other way, due to space constraints or program requirements. For many of these situations, the combined benefits of energy savings and reduced noise justify the additional costs.

Thanks to one such situation, some hikers in the Santa Cruz Mountain foothills are blissfully unaware of the home air conditioning system operating just on the other side of the park boundary.