Harvesting Energy Using Smart Materials

Julie Slaughter - julie.slaughter@etrema.com

Eric Summers - eric.summers@etrema.com

ETREMA Products, Inc.

Ames, IA 50010

Barry Arbetter

Jim Kosterman

ETREMA Products, Inc.

Ames, IA 50010

Popular version of paper 4aEA6

Presented Thursday morning, October 29, 2009

158th ASA Meeting, San Antonio, TX

Numerous forms of untapped energy sources exist all around us; from natural forms such as wind, solar, and wave, to man-made sources such as vibrations or sound. Energy harvesting is a term used to describe the capturing of this untapped energy either to power devices such as sensors, alarms, and wireless radio transmitters or to store for future use in capacitors or batteries. By efficiently converting these energy sources we will continue to drive down our dependence on fossil fuels and reduce the stress on our national power grid.

We are exploring the area of vibrational energy harvesting using a smart material known as Galfenol. Industrial and commercial equipment commonly exhibit vibrations during operation. These vibrations are energy losses that are generally accepted as a nuisance and not addressed. However, this vibrational energy can be harvested and used in variety of ways. Smart materials are materials that respond to their environment in known and predictable ways. Galfenol is a magnetic smart material that responds to external vibrations by changing its magnetic state. These changes in magnetic state can be used to generate voltage and produce power on a coil wound around the material. The voltage generated as a result of converting the vibrational energy is then conditioned to match the voltage/current requirements of the devices that will be powered.

Vibrational energy harvesting is not a new concept. Several products exist in the marketplace that can perform this function. However, they only operate efficiently at one discrete frequency (the number of vibrations/second; measurement units of Hertz) known as the resonant frequency. A small deviation, less than 5 Hz, from that resonant frequency drops their efficiency by > 50%. Unfortunately, the frequency spectrum of vibrations is often not predictable, especially during power-up, power-down, and under variable loading conditions. Thus, these devices are limited with respect to harvesting energy capability. These existing systems are also fragile in nature and cannot survive exposure to significant forces, excluding them from use where large potential energy sources are available.

We developed a new kind of vibrational energy harvesting system that can harvest energy efficiently over a large frequency range and withstand large compressive and tensile forces.

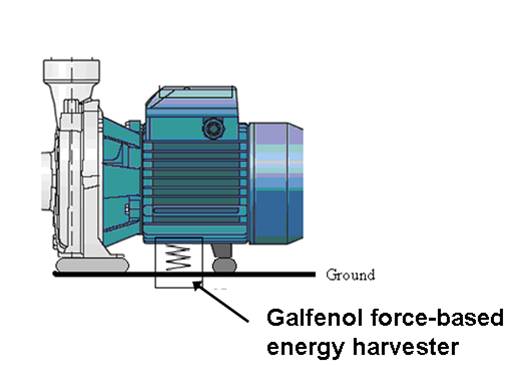

Galfenol was engineered into a bolt-like configuration for purposes of demonstrating the concept. A Galfenol rod was welded to threaded stainless steel end pieces, and energy pickup coils were wound around the Galfenol. Figure 1 shows the assembly breakout of the device, a completed assembly, and a photo of the Galfenol with and without the threaded steel end pieces. The total volume of the energy harvester was less than 2 cubic inches. Vibrational forces are applied axially to the Galfenol, resulting in a change in magnetic flux, or a magnetic state change, inducing voltage in the pick-up coils. Because vibrational forces are the mechanism generating power, the energy harvester works well across a broad range of vibrational frequencies. This energy harvesting concept is defined as a force-based energy harvester. A notional sketch showing the Galfenol force-based energy harvester installed under an industrial motor is shown in Figure 2.

Figure 1. Photos showing the Galfenol energy harvester assembly, top, and a close-up of the Galfenol material with and without threaded steel end pieces, bottom.

Figure 2. Sketch of a possible application for the Galfenol force-based energy harvester; using the energy harvester to harvest vibrational energy from an electrical motor.

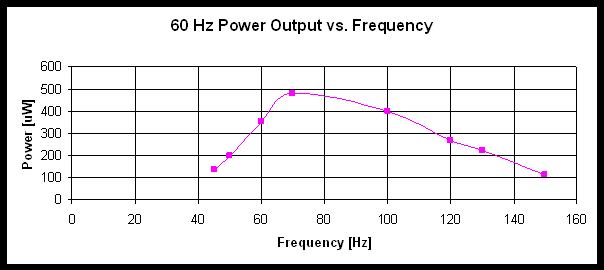

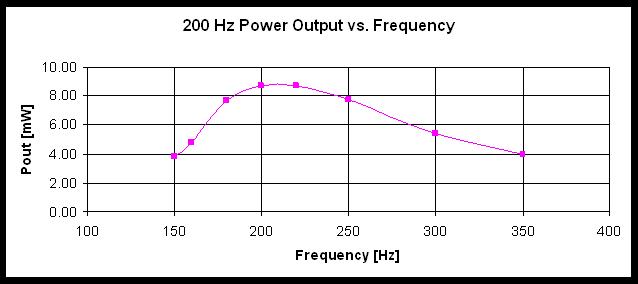

Testing of the Galfenol energy harvester was accomplished by inputting various vibrational frequencies under different dynamic loads and monitoring the voltage output of the device. Attaching a resistive load, similar to a sensor or wireless radio transmitter, to the Galfenol energy harvester allowed output power to be determined. Figure 3 and 4 show the harvested output power as a function of the vibrational frequency. Figure 3 test results are based on an electronics package optimized for a 60 Hz vibration frequency. Figure 4 test results are based on an electronics package optimized for a 200 Hz vibration frequency. Notice how the output power is maintained over a large frequency range for both configurations. It should also be mentioned that the electronics packages can fit onto small circuit boards and do not significantly increase the overall size or complexity of the system. Finally, the Galfenol energy harvester has yet to be tested to determine the maximum power output capability of the device. Testing at larger dynamic loads will increase the harvested power as will increasing the vibrational frequency.

Figure 3. Galfenol energy harvester power output as a function of vibrational frequency with the associated electronics optimized for 60 Hz performance. A peak power of 0.5 mW was harvested and a half-power bandwidth of 75 Hz was measured.

Figure 4. Galfenol energy harvester power output as a function of vibrational frequency with the associated electronics optimized for 200 Hz performance. A peak power of 8.7 mW was harvested and a half-power bandwidth of 165 Hz was measured.

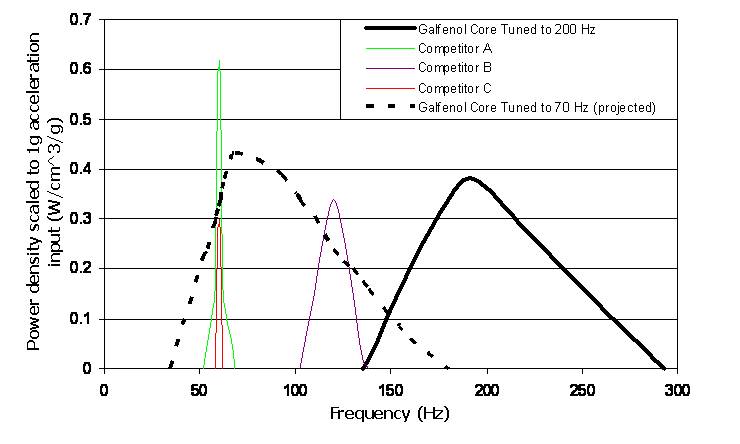

Performance comparison between the Galfenol energy harvester and existing energy harvesting technologies was completed. Figure 5 shows the power density of the device versus vibrational frequency. The Galfenol energy harvester developed provides excellent energy harvesting capabilities over a broader frequency bandwidth without sacrificing significant peak output power capability. The Galfenol energy harvesting technology developed is a disruptive technology when compared to existing systems.

Figure 5. A comparison of various vibrational energy harvesting technologies as a function of vibrational frequency.