Acoustic Comparison of Pneumatic and

Electric Jackleg Drills Used in the Mining Industry

Hugo E. Camargo - HCamargo@cdc.gov

Jeffrey S.

Peterson - JPeterson@cdc.gov

Peter G.

Kovalchik - PKovalchik@cdc.gov

Lynn A. Alcorn -

lyn3@cdc.gov

National

Institute for Occupational Safety and Health

Popular version

of paper 3aNCc2

Presented on

Wednesday morning, April 21

159th

ASA Meeting, Baltimore, Maryland.

Disclaimer: The findings and conclusions in this article are those of the author(s)

and do not necessarily represent the views of the National Institute for

Occupational Safety and Health.

A study of U.S. western hard-rock miners noise exposure revealed that

96% of mining machine operators are exposed to noise levels exceeding the Permissible

Exposure Level (PEL), with jackleg drill

operators having the most rapid noise dose accumulation rate1. Jackleg

drills, simply referred to as drills throughout this article, are used to

drill blast holes that are filled with explosives. They are also used to drill

bolt holes, through which bolts are driven for roof support, especially in

narrow situations. Traditionally, these drills have been driven by pneumatic

power, i.e. compressed air. However, there are drills currently available that

are powered by electricity. These electric drills are less noisy and have lower

vibration levels than pneumatic drills, and constitute an attractive alternative

to pneumatic drills. However, electric drills also have lower penetration rates

than pneumatic drills2. As a consequence, the reduced noise of the

electric drills tends to be overshadowed by the slower penetration rates. One

of the outstanding issues to be addressed is to quantify the noise exposure reduction

benefits of the electric drills, so that their value can be assessed by mine

operators.

In this context, the

National Institute for Occupational Safety and Health (NIOSH) conducted a study

to assess the acoustic performance of pneumatic drills and electric drills used

in the mining industry. The objective of

the study was to determine, from an occupational noise exposure perspective, whether

electric drills constitute a viable alternative to pneumatic drills. This

article presents the most relevant results from the study. A more comprehensive

report can be found in Reference 3.

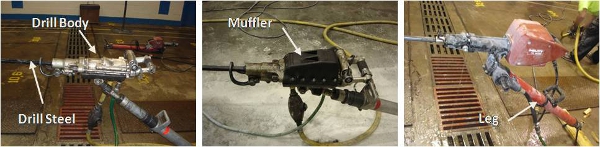

(a)

Pneumatic drill. (b)

Pneumatic drill with muffler. (c)

Electric drill.

Figure 1. Drills under test.

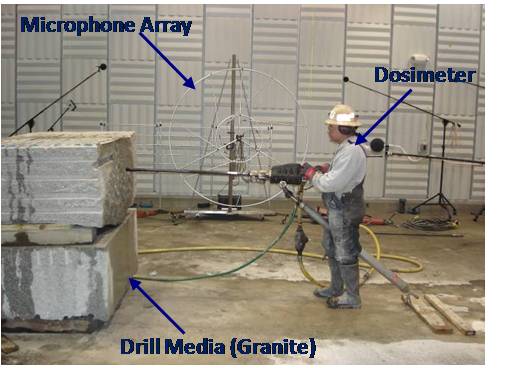

Figure 2. Experimental setup for noise source identification

measurements.

3 RESULTS

3.1 Noise Source

Identification

Noise source

identification was conducted to determine the physical location and the

frequency content of the dominant drill noise sources. To accomplish these tasks,

a microphone array was used to measure the acoustic field. The data were then

processed using a beamforming algorithm. This algorithm focuses the array to a

particular point in space where it is suspected a noise source is located. The

results from this processing are acoustic maps in one-third octave frequency bands.

Figure 3 shows typical beamforming

acoustic maps. From these maps it can be observed that for the pneumatic drill

without muffler, the dominant noise source is located at the drill body. When a

muffler is installed, the sound is reduced by approximately 5 dB and now two

noise sources are present; one at the drill body and one at the

drill-steel-rock interaction place. Therefore, the muffler reduces the source

at the drill to a level that is comparable to the noise source at the drill

bit-rock interaction place. When the electric drill is used, it can be seen

that the sound is further reduced by approximately 9 dB, and now the dominant

source is located at the drill-steel-rock interaction place.

(a) Pneumatic drill. (b)

Pneumatic drill with muffler. (c) Electric drill.

Figure

3. Typical acoustic maps for

the tested drills (2000 Hz).

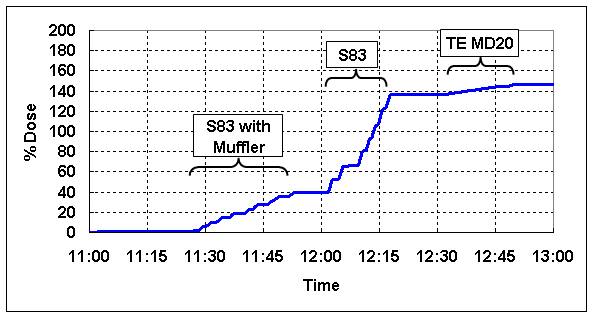

3.2 Noise Dose Accumulation

The cumulative dose was

measured using a dosimeter placed at the operators shoulder, as shown in

Figure 2. Figure 4 shows the cumulative dose as a function of time

while drilling into concrete. In this figure, the three segments corresponding

to the dose accumulated while operating each tested drill are clearly

identified. From this figure, it can be seen that the operator accumulates dose

more rapidly while operating the pneumatic drill. These results were used to

estimate average cumulative dose rates per minute which are summarized in Table

1.

Figure 4. Cumulative dose for the three tested drills while

drilling in Concrete.

Table 1. Operator cumulative noise dose.

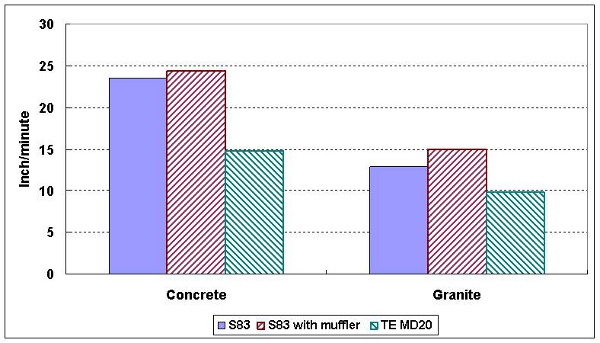

3.3 Penetration Rate

The penetration rate was determined

by dividing the hole depth by the time required to drill a particular hole. The

penetration rate of the electric drill, as shown in Figure 5, is approximately 60%

the penetration rate of the pneumatic drill. Using these penetration rates, and

the cumulative dose, presented in Table 1, allows estimating the time required

to drill a reference 1.2 meter (48 inch) hole. It would take 1.98 minutes to

drill a reference hole in concrete using the S83 with muffler as opposed to

3.24 minutes using the TE MD20. Similarly, it would take 3.22 minutes to

complete a 1.2 meter (48-inch) reference hole in granite using the S83 with

muffler, while it would require 4.89 minutes to drill the same hole using the

TE MD20 drill. During this time, the operator of the pneumatic drill with

muffler would accumulate approximately 8.1% dose, while the operator of the

electric drill would accumulate 4.2% of the maximum allowable dose.

Figure 5. Penetration rate.

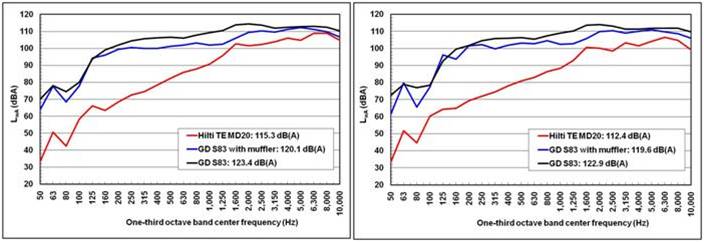

3.4 Determination of Sound Power Levels

The sound power level is the actual sound energy emission of a device.

Thus, it is a valuable tool for comparing the noise generated by the drills under

test. The sound power level radiated by the tested drills while drilling into

granite is presented in Figure 6a. Similarly, Figure 6b shows the sound power

level radiated by the drills while drilling into concrete. Figure 6a reveals

that the difference in sound power level between the pneumatic drill without

muffler and the electric drill is 10.5 dB(A). When the muffler is

installed, the difference in sound power level between the pneumatic drill

(with muffler) and the electric drill is reduced to 7.2 dB(A). Figure 6b shows a similar trend when

drilling into concrete. The difference in sound power level between the pneumatic

drill without muffler and the electric drill is 8.1 dB(A). When the muffler is installed, the difference between the

pneumatic drill (with muffler) and the electric drill is 4.8 dB(A).

(a)

Granite.

(b) Concrete.

Figure 6. Sound power level radiated by the drills.

A comparison between a

pneumatic drill and an electric drill was conducted by NIOSH. The results from

the various tests conducted in the study indicate that from an occupational noise exposure perspective, the acoustic performance of the electric

drill, despite its slower penetration rates, overcomes the acoustic performance

of traditional pneumatic drills. These findings provide quantitative

information to assist the mine operator in balancing potential miner hearing

loss and productivity with a viable means to meet regulations.

5 ACKNOWLEDGMENTS

The authors would like to thank Gary Roberts, Ron Key, and Rusty Lynn

Howard for providing the drills, and to Patrick McElhinney for his support for

setting up the test.

6 REFERENCES

3. Camargo, H.E., Peterson, J.S., Kovalchik,

P.G., and Alcorn, L.A., Acoustic Assessment of Pneumatic and Electric Jackleg

Drills Used in the Mining Industry, Proceedings of NoiseCon 2010, Baltimore,

MD, April19-21, 2010.