Less Sound

Underground: Reducing Roof Bolting Machine Drilling Noise

M. Jenae Lowe- jli7@cdc.gov

J. Shawn Peterson - jnp3@cdc.gov

David S. Yantek - dcy6@cdc.gov

Lynn A. Alcorn - lyn3@cdc.gov

National Institute for Occupational Safety and Health

Office of Mine Safety and Health Research

626 Cochrans Mill Road

Pittsburgh, Pennsylvania 15236

Robert Michael - bmichael@corryrubber.com

Penn State Erie - The Behrend College, Corry Rubber Corporation

601 West Main Street

Corry, Pennsylvania 16407

Popular version of paper 3aNCc3

Presented Wednesday morning, April 21, 2010

159th ASA Meeting, Baltimore, Maryland

Disclaimer: The findings and conclusions in this report are those of the author(s) and do not necessarily represent the views of the National Institute for Occupational Safety and Health. Reference to specific brand names does not imply endorsement by the National Institute for Occupational Safety and Health.

1 Introduction

National Institute for Occupational Safety and Health (NIOSH) researchers strive to reduce noise-induced hearing loss for coal miners. The highest occurrence of hazardous noise exposure in the United States is within the mining industry, where 24% of miners have a reported hearing loss as a result1,2. To find out the causes, NIOSH reviewed surveillance data from the Department of Labor Mine Safety and Health Administration (MSHA) on noise exposure in the mining industry. This study revealed which machine operators exceed 100% noise dose per the MSHA Permissible Exposure Level (PEL) the noise limit a mine worker can be exposed to for their shift3. To reduce noise overexposure for miners, researchers have developed noise controls that reduce the sound at the operators position. For one machine in particular, a roof bolting machine (RBM), NIOSH partnered with Corry Rubber Corporation and Kennametal, Inc. to develop a suite of noise controls. This article presents the most significant findings from that research. A detailed report on the noise control suite is listed in the reference section4. The control suite reduces sound levels at the operators ear by over 77%. This is significant because an RBM operator is the second-most likely of all underground coal mining equipment operators to be overexposed to noise3.

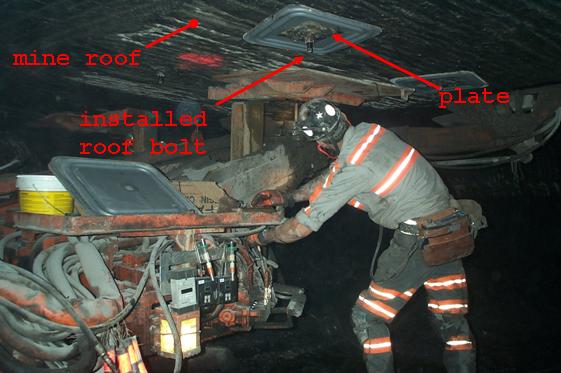

After coal has been removed, RBMs are used to temporarily stabilize the mine roof while installing roof bolts to support it. In other words, large bolts are placed in the mine roof to connect the rock and prevent cave-ins. To install the bolts, the RBM operators drill holes into the mine roof using drill bits attached to hollow steel bars called drill steels (Figure 1). After a hole is drilled, a roof bolt is inserted to connect the overlying rock layers, thereby supporting the roof (Figure 2).

Figure 1. Hexagonal and round drill steels for

a 1 3/8 (35-mm) diameter drill bit (upper) and two examples of drill bits

(lower) 1 and 1 3/8 (25 mm and 35 mm).

Figure 2. A

roof bolting machine in an underground coal mine.

Prior studies have shown that drilling exposes RBM operators to the highest sound levels compared with all other tasks in their typical work day5. Therefore, the most efficient method of reducing noise-induced hearing loss for RBM operators is to reduce drilling noise. NIOSH measurements on RBMs found that the highest sources of drilling noise were near the chuck, which holds the drill steel, and near the drill bit, which cuts holes into the rock6. To reduce this noise, NIOSH and its industry partners developed a suite of controls that target sound generated in these areas.

2 Noise

control design

Noise controls can take a variety of forms. One type is a barrier or enclosure that blocks noise from reaching a listeners ears. Another common control isolates vibrations from one component from traveling to another that more readily generates noise when vibrating. Both of these types of noise treatments were used for the RBM control suite, which includes a bit isolator, chuck isolator, and collapsible drill steel enclosure (CDSE).

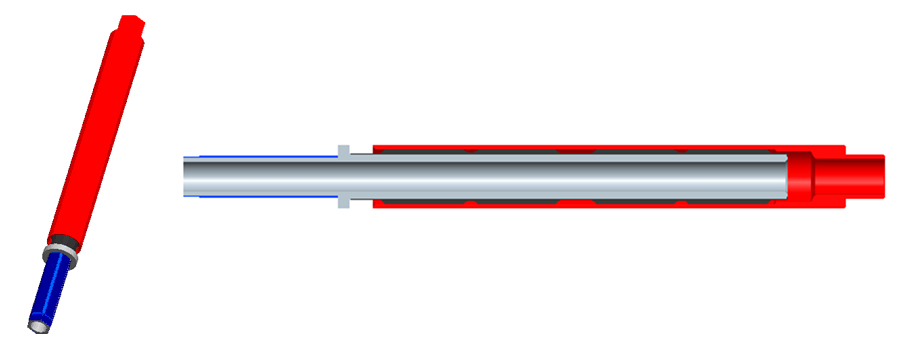

The bit and chuck isolators are similar to a rubber motor mount that reduces vehicle engine vibrations being transmitted into the cabin. A bit isolator is essentially a steel rod inside of an outer steel sleeve, or tube, with a rubber layer sandwiched between the two (Figures 3-4). The rubber layer makes it harder for vibration from the sleeve to travel to the rod. Installing the bit isolator between the drill steel and bit isolates vibrations at the drill bit and prevents them from traveling down into the drill steel, which tends to radiate noise. This effect reduces material vibration and as a result less noise is created during drilling. A chuck isolator is similar, except it fits between the chuck and the drill steel.

Figure 3. Model of bit isolator design. The blue and gray colors indicate the inner member, red indicates the outer steel member, and black indicates the elastomer layer.

Figure 4. Picture of bit isolator design, two units disassembled.

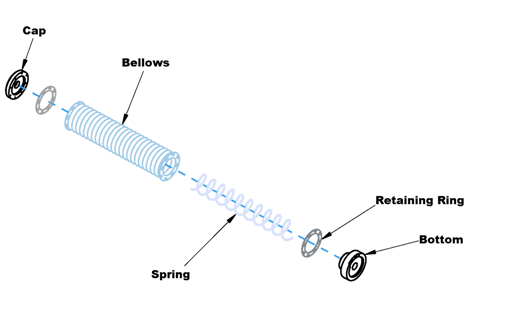

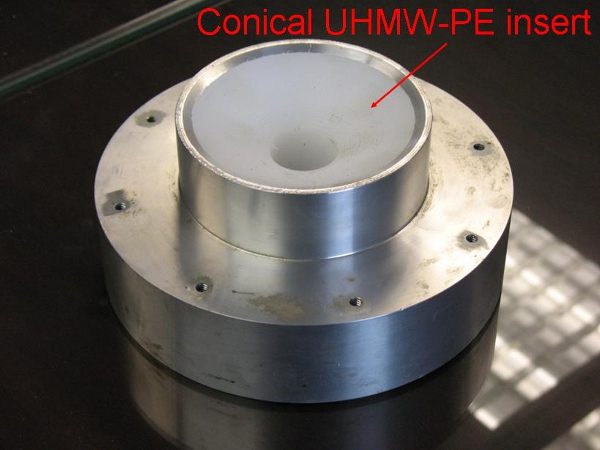

The CDSE encloses the drill steel to block noise from reaching the operators ear. It consists of a bellows to enclose the drill steel, a hinge that allows the CDSE to move out of the way for roof bolt installation, a cap to help the CDSE seal against the roof, and customized hardware to install the CDSE onto a specific RBM (Figure 5). Each CDSE bellows is supported by a straight cylindrical spring which keeps the bellows upright and collapses as the chuck of the RBM rises during drilling. A funnel-shaped plastic insert within the CDSE bottom, as shown in Figure 6, guides the drill steel into place in the chuck7.

Figure 5. Exploded view of the Collapsible Drill

Steel Enclosure (CDSE).

Figure 6. Bottom of the Collapsible Drill Steel Enclosure (CDSE), showing the conical plastic insert used to guide the drill steel into place when inserting it into the chuck.

NIOSH designed the CDSE for ease of use. Before drilling, the operator installs a drill steel through the top of the CDSE and into the chuck. At the beginning of the drilling cycle, the CDSE is fully extended. A gap between the cap and the roof allows the operator to see the drill bit and start the hole. As the chuck rises, the gap closes until the cap is flush with the roof. The CDSE then collapses as drilling continues. When drilling is completed, the operator swings the CDSE to the side and installs the roof bolt as usual.

3 Test

setup and results

NIOSH evaluated various noise control combinations to determine how much they reduced drilling noise. They performed testing outside, drilling into granite. Granite was chosen for the test material because of its consistency, which ensures repeatable results. NIOSH ran the roof bolter at settings that are typical for drilling into harder materials such as granite8. A microphone measured sound pressure levels at the operators right ear location. The results are summarized in Table 1 below.

Table 1.

Summary of operators right ear A-weighted sound level results.

|

Configuration |

Overall Sound Level, dB(A) |

Noise Reduction from Baseline (dB) |

|

Baseline |

106 |

|

|

75 Durometer Bit Isolator |

102 |

4 |

|

75 Durometer Chuck Isolator |

104 |

2 |

|

Bit Isolator and Chuck Isolator |

101 |

5 |

|

Bit Isolator and CDSE |

94 |

12 |

|

Bit Iso, Chuck Iso, and CDSE |

93 |

13 |

The results showed that the bit and chuck isolators reduced noise. Further, NIOSH learned that the rubber used in them could survive over 120 hours of drilling without failure. Based on this, NIOSH and their partners began work to optimize the rubber used to provide the best balance between noise control and durability. The initial rubber chosen for the bit and chuck isolators was stiffer, which means it would deflect less and therefore be more durable. By using a more flexible material it could move more when exposed to vibration which would dissipate more of the energy that could be converted into sound. By disbursing more of this energy, the more flexible rubber would reduce more noise.

Sound measurements from this optimization study have shown that the more flexible the rubber is, the more it reduces drilling noise. As long as the rubber also proves to be durable, the bit and chuck isolators can be further optimized between sound reduction and durability by changing the rubber properties. Therefore, using different materials could provide an even greater reduction than the 13 dB(A) yielded by the control suite tested earlier.

4 Conclusions

In summary, the noise exposure of mine workers is a serious problem that NIOSH is dedicated to addressing through the development of noise controls. While this work is directly applicable to miners, many of the technologies developed can be applied to other industries. In this case, each noise control that was developed reduced RBM operator drilling noise. Various combinations of controls can be used, depending on what a mine needs to bring an operator under the PEL. Currently, the greatest reduction achievable is 13 dB(A), or a 77% reduction in sound pressure. However, even larger reductions are possible with further development of bit and chuck isolator materials.

5 ACKNOWLEDGEMENTS

The authors would like to thank Pat McElhinney for his assistance with running the roof bolter, Ernie Ferro from Corry Rubber Corporation for his expertise and design assistance with the chuck and bit isolators, Chad Swope and Doug Bise from Kennametal, Inc. for machining chuck and bit isolator samples and providing technical advice on roof bolting parameters, and Hugo Camargo for assisting with the sound power level testing.

6 references

S. Tak, R.D. Davis, G.M. and Calvert, Exposure to hazardous workplace noise and use of

hearing protection devices among US workersNHANES, 19992004, American Journal of Industrial Medicine, 52, 358371, (2009).

S. Tak and G.M. Calvert, Hearing difficulty attributable to employment by industry and occupation: An analysis of the National Health Interview SurveyUnited States, 1997 to 2003, Journal of Occupational and Environmental Medicine, 50, 4656, (2008).

Title 30 CFR Part 62, 2000-2005, U.S. Department of Labor, Mine Safety and Health Administration, Information Resource Center, Denver CO.

M. Jenae Lowe, J. Shawn Peterson, David S. Yantek, Lynn A. Alcorn, and Robert Michael, A control suite to reduce roof bolting machine drilling noise, Proceedings of Noise-Con 2010, Baltimore, MD, April 19-21, (2010).

J. Shawn Peterson and Lynn A. Alcorn, Results of noise measurements from underground testing of a roof bolting machine duty cycle, Noise-Con Proceedings, 116(1), 437-446, (2007).

Robert Michael, David Yantek, J. Shawn Peterson, and Ernie Ferro, The evolution of drill bit and chuck isolators to reduce roof bolting machine drilling noise, Society for Mining, Metallurgy, and Exploration, Inc., Annual Meeting Preprints, Littleton CO, (2010).

National Institute of Occupational Safety and Health, Collapsible Drill Steel Enclosure A device for reducing roof bolting machine noise exposure. <http://www.cdc.gov/niosh/mining/products/product173.htm>, accessed March 15, 2010.

J.S. Peterson, P.G. Kovalchik, and R.J. Matetic, Sound power level study of a roof bolter, in Transactions of Society for Mining, Metallurgy, and Exploration, Inc., 320, 171-177, edited by W.R. Yernberg, Society for Mining, Metallurgy, and Exploration, Inc., Littleton CO, (2006).