Listen to Bone Quality:

How Ultrasound Helps to Reveal Microstructure and Elastic Function in Bone

Kay Raum -

kay.raum@charite.de

Julius

Wolff Institute & Berlin-Brandenburg School for Regenerative Therapies

Charit

- Universittsmedizin Berlin

Augustenburger

Platz 1

13353 Berlin, Germany

Quentin Grimal -

quentin.grimal@upmc.fr

Laboratoire dImagerie Paramtrique

CNRS, Universit Pierre et Marie Curie-Paris 6

F75006

Paris, France

Alf

Gerisch - gerisch@mathematik.tu-darmstadt.de

Fachbereich

Mathematik

Technische

Universitt Darmstadt

Dolivostr. 15

64293

Darmstadt, Germany

Pascal Laugier -

pascal.laugier@upmc.fr

Laboratoire dImagerie Paramtrique

CNRS, Universit Pierre et Marie Curie-Paris 6

F75006 Paris, France

Popular version of paper 5pBB9

Presented Friday afternoon,

April 23, 2010

159th ASA Meeting, Baltimore,

MD

Introduction

Sophisticated technical materials that are used in

everyday life are often inspired by nature. Lightweight honeycomb constructions

and carbon fiber reinforced sandwich composites, for example, are used to

construct airplanes, cars or modern sports equipment and aim to optimize

various properties, e.g. weight, toughness and strength that cannot be achieved

by a single material. Examples of adopting structural concepts from nature for

the design of technical materials and the construction of devices date back

centuries, to the first concept of a flying machine by Leonardo da Vinci in 1488. However, our current knowledge about

natural concepts to achieve a desired function is still limited and the

investigation of functional consequences of specific design variations is the

focus of the rather young and growing research discipline, called Biomimetics.

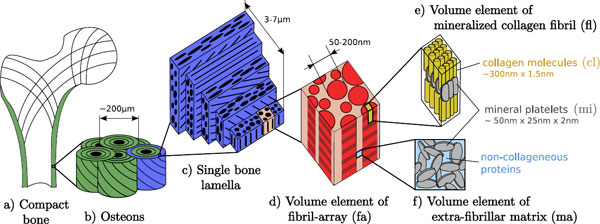

Hard biological tissues, e.g. mineralized tendons,

bone and teeth are natural examples of achieving unique combinations and also

great variability of stiffness and strength. All of these tissues have a common

building block a collagen fibril that is reinforced by small mineral

crystals. One of the striking features of these tissues is the ability to adapt

to variable loading conditions by multiple but well organized structural

arrangements of this building block at several levels of hierarchical

organization (Fig. 1).

Figure 1. Hierarchical structure of compact bone: a) compact

bone in long diaphysis; b) osteons

formed by lamellae; c) bone lamellae, made of a sandwich compound of

mineralized collagen fibril films with variable orientations; d) film of

mineralized collagen fibrils with a single orientation e) basic building block:

the mineralized collagen fibril; f) extra-fibrillar

matrix. From Reisinger et al. [1].

For survival, the skeleton of animals and humans has

to provide stability, support and protection of the internal organs against

mechanical impacts in combination with the ability of fast and energy efficient

locomotion that is needed to collect food, hunt or escape from other hunting

animals. Moreover, this functionality has to be preserved throughout lifetime,

which requires adaptation to variable conditions during maturation and ageing,

but also repair mechanisms that allow both, an incremental repair of microdamage and restoration of macroscopic defects, i.e.

fractures.

In order to achieve these goals, bone uses various

design concepts, e.g. reinforcing a soft and flexible collagen matrix by stiff,

but brittle mineral particles, sandwich compounding of anisotropic

(directional) films, weight reduction by directional pores and spongy networks.

Adaptation and repair is realized by an army of cells specialized either in

sensing, mining or construction of bone tissue. Altogether this leads to a

highly dynamic, lightweight stiff and tough compound material that is usually

able to maintain its function throughout lifetime.

This principle of bone adaptation is widely accepted

as Wolffs law of bone adaptation based on the

classic work of Julius Wolff entitled Das Gesetz der Transformation der Knochen (The Law of Transformation of Bone),

published in 1892 [2]. Since then mechanical properties of bone have been

intensively investigated by macroscopic to nanoscopic

mechanical testing, imaging and numerical approaches.

Although many details of the genetics, biology,

pathology and mechanics of bone have been uncovered, we still lack of a

detailed understanding of bone structure at the nano-

and microscales. Existing theoretical bone models

only allow us a limited description of macroscopic function (e.g. stability and

resistance to failure) based on structural and compositional features at

smaller hierarchical levels of organization. However, such models are crucial,

e.g. to i) understand the mechanical and biological

mechanisms of bone adaptation, ii) predict the outcome of anabolic (bone

building) or antiresorptive treatment strategies,

iii) define design concepts for technical materials with equally good combinations

of properties like bone and iv) provide a better understanding of the origin of

the mechanical resistance properties of bones. The latter is of particular

importance, as it would help researchers to design a new class of non-invasive,

non-ionizing, ultrasound based diagnostic systems that would allow for a safe

and reliable prediction and monitoring of fracture risk and fracture healing.

Towards this goal, both experimental data of

heterogeneous elastic and structural parameters from all length scales (from

the centimeter to the nanometer scale) and theoretical models that can simulate

the deformation behavior based on these data are required.

Quantitative Ultrasound

If sound waves propagate through a material, their

elastic interactions cause small reversible deformations (compression,

expansion, or shearing). The velocities of these deformations are determined by

the elastic properties and the mass density of the material. This principle has

been used for decades for the non-invasive and nondestructive evaluation of

technical materials and biological tissues [3-6]. Focused ultrasound

transducers that emit short pulses and measure the reflection amplitude can be

used like a virtual fingertip to probe the elastic response of the surface of

a material. By scanning the transducer over the surface, elastic maps can be

obtained. The size of this virtual fingertip depends upon the numerical

aperture of the sound field and the acoustic frequency, and can be varied over

several orders of magnitude (from 10 mm at 100 kHz down to 0.5 m at 2 GHz)

[7-14].

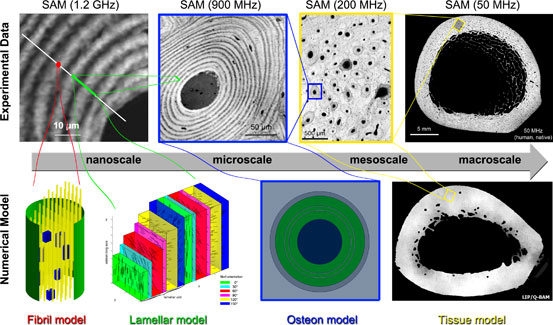

Figure 2. Acoustic images (top) and numerical models (bottom)

of human bone cross-sections. The gray-scale in the acoustic images corresponds

to the local elastic response of the tissue to the incoming wave (bright =

stiff; dark = soft). From left to right:

Ultrasound in the GHz range reveals the apparent sandwich compound

structure of fibril bundles. The large dark spot is a Haversian

canal hosting blood vessels and the small spots are osteocyte

lacunae, hosting bone cells. These data (in combination with other input data)

are used to construct the fibril, lamellar, and osteon

models. At 200 MHz parallel and elliptical tissue structures (osteons) as well as a porous microstructure can be

observed. These data are the basis for the tissue model.

The Bottom-up Approach

A bottom-up approach requires experimentally

assessed structural, compositional and elastic data at each hierarchical level

of organization from the nanoscale to the macroscale (Fig. 2). These data can be obtained by

ultrasound with the frequency tuned to the structural dimension at each

hierarchy level and site-matched complementary data (e.g. mineralization from

synchrotron radiation micro computed tomography (SR-CT) [7, 8, 10, 11].

Simplified volume elements that resemble the major structural design features,

but also incorporate degrees of freedom for dynamic adaptation (e.g. a

time-dependent change of mineralization) can then be constructed (Fig. 2). The

effective elastic properties of such volume elements can be computed by

numerical homogenization approaches [15, 16]. For example, the data can be

translated into a so-called Finite Element (FE) mesh. By numerical deformation

analyses, i.e. a virtual compression and calculation of the resulting

deformation, the elastic parameters that describe a similarly behaving

homogeneous material, i.e. a material without any structure or variation of

material properties, can be derived.

Homogenization from the nano-

to the macroscale is performed in a series of steps:

the effective material properties obtained at one hierarchical level are used

to build the volume element at the next scale. The advantage of this approach

is a dramatic reduction of complexity without the loss of structure-functional

relationships. Furthermore, experimental data at a given next length scale

serve both for the validation of the homogenization model and as input for the

next homogenization step.

Results

We have derived the elastic stiffness parameters, i.e.

the elastic stiffness tensor and the degree of mineralization in human cortical

bone at several length scales by site-matched Scanning Acoustic Microscopy

(SAM) and SR-CT. From these data, hierarchical models have been developed that

connect the nanoscale with the macroscale

(Fig. 2) and describe the elastic behavior of the tissue at all length scales.

Our results indicate that some of the previously proposed fibril arrangements

at the nanoscale [17] do not result in the

experimentally observed elastic properties at the next length scale (microscale). However, our data support the model of a

twisted plywood structure [18, 19]. This model

uses only a simple construction rule, but allows in principle the design of

several previously reported fibril arrangements by a variation of the thickness

of individual fibril layers. At the next length scale (mesoscale),

the effects of material properties and the porous network have been evaluated

numerically. Moreover, local variations of the mesoscale

structural and elastic properties within the femoral shaft appear to be related

to an inhomogeneous strain distribution resulting from external (macroscopic)

stresses by weight and muscle forces.

Conclusion

Ultrasound provides a unique and to date almost

unexplored way to listen to bone quality. In contrast to other mechanical or

imaging techniques, this ultrasound-based elastic imaging approach combines the

possibility to assess structural and material properties of the tissue across

multiple length scales. In order to handle this complex information,

established engineering tools, e.g. finite element analyses and homogenization

techniques have been employed. By utilizing such a combination, the principal

mechanisms leading to the exceptional combination of toughness and strength, as

well as the change of these properties throughout the course of bone ageing or

pathologies, can be investigated.

Acknowledgments

This work has been conducted within the European

Associated Laboratory Ultrasound Based Assessment of Bone (ULAB) and was

supported by the Deutsche Forschungsgemeinschaft

within the priority program SPP1420 Biomimetic

Materials Research: Functionality by Hierarchical Structuring of Materials

(grant Ra1380/7).

References

[1] Reisinger,A.G., Pahr,D.H., Zysset,P.K., Sensitivity analysis and parametric study of

elastic properties of an unidirectional mineralized bone fibril-array using

mean field methods, Biomech. Model. Mechanobiol. 2010.

[2]

Wolff,J.,

Das Gesetz der Transformation der Knochen. Berlin, Verlag von August

Hirschwald. 1892.

[3] Ashman,R.B., Cowin,S.C., Rho,J.Y., Van Buskirk,W.C., Rice,J.C., A continous wave

technique for the measurement of the elastic properties of cortical bone, J. Biomech. 17 (5), 1984, 349-361.

[4] Lees,S., Heeley,J.D., Cleary,P.F., A study of some properties of a sample of

bovine cortical bone using ultrasound, Calcif. Tissue

Int. 29 (2), 1979, 107-117.

[5] Rho,J.Y., An ultrasonic method for measuring the elastic

properties of human tibial cortical and cancellous bone, Ultrasonics 34 (8), 1996, 777-783.

[6] Van Buskirk,W.C., Cowin,S.C., Ward,R.N., Ultrasonic measurement of orthotropic elastic

constants of bovine femoral bone, J. Biomech. Eng.

103 (2), 1981, 67-72.

[7] Raum,K., Microelastic imaging of

bone, IEEE Trans. Ultrason. , Ferroelect.

, Freq. Contr. 55 (7), 2008, 1417-1431.

[8] Raum,K., Hofmann,T., Leguerney,I., Saied,A., Peyrin,F., Vico,L., Laugier,P., Variations of microstructure, mineral density

and tissue elasticity in B6/C3H mice, Bone 41 (6), 2007, 1017-1024.

[9] Raum,K., Kempf,K., Hein,H.J., Schubert,J., Maurer,P., Preservation of microelastic

properties of dentin and tooth enamel in vitro--a scanning acoustic microscopy

study, Dent. Mater. 23 (10), 2007, 1221-1228.

[10] Raum,K., Leguerney,I., Chandelier,F., Talmant,M., Saied,A., Peyrin,F., Laugier,P., Site-matched assessment of structural and

tissue properties of cortical bone using scanning acoustic microscopy and

synchrotron radiation CT, Phys. Med. Biol. 51 (3), 2006, 733-746.

[11] Hofmann,T., Heyroth,F., Meinhard,H., Franzel,W., Raum,K., Assessment of composition and anisotropic elastic

properties of secondary osteon lamellae, J Biomech. 39 (12), 2006, 2284-2294.

[12] Hube,R., Mayr,H., Hein,W., Raum,K., Prediction of

biomechanical stability after callus distraction by high resolution scanning

acoustic microscopy, Ultrasound Med. Biol. 32 (12), 2006, 1913-1921.

[13] Raum,K., Leguerney,I., Chandelier,F., Bossy,E., Talmant,M., Saied,A., Peyrin,F., Laugier,P., Bone

microstructure and elastic tissue properties are reflected in QUS axial

transmission measurements, Ultrasound Med. Biol. 31 (9), 2005, 1225-1235.

[14] Raum,K., Jenderka,K.V., Klemenz,A., Brandt,J., Multilayer

analysis: Quantitative scanning acoustic microscopy for tissue characterization

at a microscopic scale, IEEE Trans. Ultrason. , Ferroelect. , Freq. Contr. 50 (5), 2003, 507-516.

[15] Parnell,W.J., Grimal,Q., The

influence of mesoscale porosity on cortical bone

anisotropy. Investigations via asymptotic homogenization, J R. Soc. Interface 6

(30), 2009, 97-109.

[16] Grimal,Q., Raum,K., Gerisch,A., Laugier,P.,

Derivation of the mesoscopic elasticity tensor of

cortical bone from quantitative impedance images at the micron scale, Comput. Methods Biomech. Biomed Engin. 11 (2), 2008, 147-157.

[17] Wagermaier,W., Gupta,H.S., Gourrier,A., Burghammer,M., Roschger,P., Fratzl,P., Spiral

twisting of fiber orientation inside bone lamellae, Biointerphases

1 (1), 2006, 1-5.

[18] Giraud-Guille,M.M., Besseau,L., Martin,R., Liquid crystalline assemblies of collagen in

bone and in vitro systems, J. Biomech. 36 (10), 2003,

1571-1579.

[19] Giraud-Guille,M.M., Twisted plywood architecture of collagen

fibrils in human compact bone osteons, Calcif. Tissue Int. 42 (3), 1988, 167-180.