Glass Breakage

by Blasts - A Prediction Model and Real-world Validation

Louis C. Sutherland - lou-sutherland@juno.com

LCS Acoustics

Popular version of paper 3pNS2

Presented Wednesday afternoon, April 21, 2010

159th ASA Meeting, Baltimore, MD

It is not surprising that windows are usually the

structural element in a building most subject to damage by the overpressure

pulse from an explosion. After all, what

other building element can so easily be broken by a baseball hit by an unlucky

young batter in a neighborhood baseball game played too close to your home. A powerful statistical model for damage to

windows from similar impulsive pressure loads was developed in 1976 by R.L Hershey

and T.H. Higgins for the FAA in a study concerning

window damage from sonic booms. This model was used to predict the

statistical probability of damage to windows in an apartment complex exposed to

blast overpressure from a accidental explosion of a small, solid rocket motor undergoing

a vibration test in a nearby environmental test facility. The apartment complex consisted of 9

buildings with 738 windows located at distances of 430 to 980 ft from the blast

source as portrayed below in Fig. 1. The

windows faced different directions relative to the incident blast wave with

most of the 53 broken windows facing the blast source. Fortunately, no one was injured by this

blast.

This paper reviews the

blast loading on the windows which faced different directions relative to the incident

blast wave, the resulting blast-generated structural stress in the windows and

the statistical prediction of damage to these windows from this blast.

Based on the 20 lb weight of the rocket motor, a

knowledgeable explosions expert estimated the blast was equivalent to a charge

of about 30 lb of

The expected time history of the pressure pulse from such a

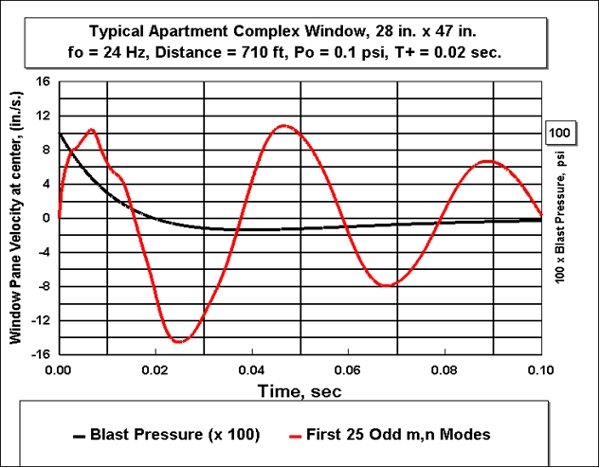

The structural velocity at the center of the glass pane

exhibits the characteristic sinusoidal-type vibration expected for a structure

vibrating in all its resonant modes. The

fundamental frequency for vibration of the window pane was calculated to be 24 Hertz (cycles per second) for the 28 x 27 in.

window.

From well-verified blast prediction models, the peak

effective blast pressure at the face of this window, including a 2 to 1 blast

pressure reflection factor at the window surface, was estimated to be 0.2 lbs

per square inch. This corresponds to a peak sound pressure level of about 156

dB.

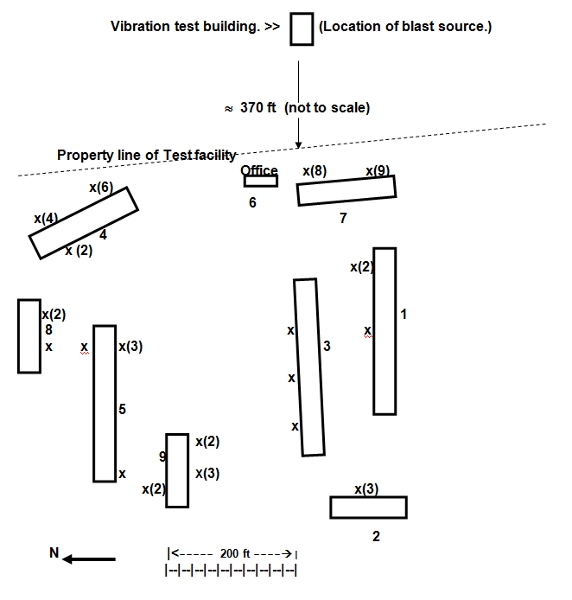

Figure

1. Geometry of Vibration test stand and the nine buildings of

the nearby apartment complex. The xs

designate the approximate location of the

broken windows and the number in

( ) indicates the number broken at his location. (No number indicates

just 1 window broken at the x location.)

Figure 2.

Time history of blast pressure and structural velocity at surface of a typical

window in the apartment complex due to the accidental explosion from 30 lbs of

The structural velocity

at the surface of the window panes is used to predict the dynamic stress in the

windows due to the incident blast wave. This utilizes a powerful relationship

between the peak stress, Spk in a sinusoidally vibrating structure

and its peak structural velocity, Vpk that was first developed by

the late Prof. F.V. Hunt in 1960. Essentially the relationship states that:

Spk = KS

[ Vpk,/ CL] psi

(1)

where

KS = a

vibration/stress proportionality factor dependent on the geometry of the

structure and Youngs Modulus of Elasticity, in psi of the material

CL = the longitudinal speed of sound, in the

material in in/s and

Vpk = the

peak modal velocity, in in/s.

(Note, that (Vpk/CL) could be

considered as a structural response Mach No.)

The peak structural stress, Spk varies directly

with the peak effective blast pressure, Peff acting on the window, the dynamic response

characteristics of the window, e,g, its resonance frequencies and its surface

weight all predictable quantities. The risk of damage to the window is defined

the Factor of Safety (FOS) involved in the window blast exposure of the window

to the blast. This FOS is simply the

ratio of the threshold for damaging stress, Sd for the window

material to the peak stress, Spk imposed by the blast or,

FOS = Sd / Spk (2)

All factors involved in

each of part of this ratio can be estimated in terms of their nominal value and

the standard deviation about this nominal mean value. The statistical

distribution of the stress threshold for damage of window glass was especially

well defined from extensive published data. The net result is that the Factor

Safety (FOS) also has a statistical distribution and a standard deviation, sFOS, which is the root

mean of the standard deviation of all the terms making up the ratio in Eq.

(2).

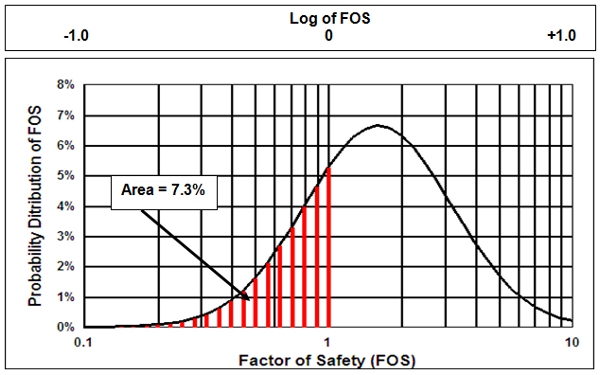

It turns out that the

logarithm of the FOS has, what is called a Normal Distribution that has the

haystack shape shown below. Damage to

a window is presumed to occur when ever the FOS is less than 1 or the Log of

the FOS is less than 0. Thus, the Probability of Damage (POD) for this

illustration is equal to the area under this normal distribution of the Log of

the FOS for which this Log is less than 0 which is 7.3 %, for this illustration.

Figure

3.

Illustration of normal distribution of

Log of Factor of Safety (FOS). Total Probability of Damage (POD) of 7.3 % is represented by the crosshatched area

under that part of the Lg[FOS] distribution for which the FOS 1 or Lg[FOS] is 0.

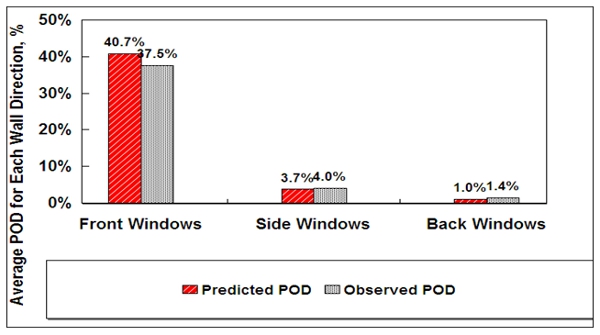

This prediction of the

POD for the windows in the Apartment Complex utilized well-known math models

for the Normal Distribution and statistical distribution data for all the terms

involved in Eq. (2), including model data,

not discussed here, on the change in effective sound levels on the

front, side and back of buildings simulating the blast wave reflection effects

for the windows in the Apartment

Complex. The average observed

and predicted POD for the windows on the front, side and back of the buildings

relative to the blast incidence direction are shown in Fig. 4 to be in good

agreement.

Figure

4. Average N-weighted, predicted versus observed POD for the

window orientation re: the blast direction for N = 80 front, N = 520 side and N

= 138 back windows.

The Fig. compares the average predicted and observed window failure rates for each of the three

window directions The agreement provides support for the basic validity of the

structural damage prediction model

employed for this study.