Deepwater Fossil Fuel Extraction and Production

Technologies – a Developing Source of Ocean Noise Pollution

Michael

Stocker - mstocker@OCR.org

Ocean

Conservation Research

P.O.

Box 559 Lagunitas, CA 94938

Popular

version of paper 3aUWa1

Presented

Wednesday morning, November 17, 2010

2nd

Pan-American/Iberian Meeting on Acoustics, Cancun, Mexico

The

era of “easy oil” is rapidly closing and more challenging

reservoirs are being developed “offshore” on outer continental

shelves using a suite of developing technologies. Deepwater (>1000

ft.– 10,000 ft.) development occurs under ambient pressures of 30 to 300

atmospheres (400 to 4000 psi.) and wellhead differential pressures of up to

20,000 psi. Active processing equipment is mounted on the sea floor to diminish

the risks and costs of the multiple pipe runs that would be required for above

sea level processing. The equipment includes separators, multi-phase and multi

stage pumps, injectors, and metering equipment. Given the potential for extreme

pressure differentials and the multi-phase nature of the product (liquids, gas,

and solids) it is likely that some of these processes generate substantial

noise. This paper is a review of the deepwater extraction and production

technologies and an overview of the physical conditions found in deepwater

fossil fuel exploration and production.

Overview

Incidental

noise pollution from human enterprise has been increasing in the ocean since

the mechanization of maritime transportation. As a consequence of the

globalization of trade, shipping noise source has increased exponentially so

that ambient noise in the ocean in certain places is ten times louder than it

was just 50 years ago from shipping noise alone. Additionally, global scale

noise is also increasing by the expansion of offshore fossil fuel development.

From exploration through production, offshore and deepwater fossil fuel

operations are raising the ambient noise levels in the ocean at an alarming

rate.

While

there is some uncertainty about the impacts of the increased ambient noise

levels on marine life, it is clear that the marine acoustic habitat of animals

that depend of acoustic communication is being adversely compromised. The

impacts may include masking of biologically significant signals such as

breeding and community coherence calls of kin, navigation cues provided by

geological or hydrodynamic features in the natural marine soundscape,

and the sounds of predators and prey.

This

concern is not isolated to whales, porpoises, and dolphins, which we know have

complex acoustical perception and communication systems, but also for fish and

perhaps even invertebrates that also rely on acoustical cues for their

survival.

Fossil

fuel exploration to production sequence

Fossil

fuel is the product of once living matter decomposing in geological formations

that due to pressure, heat, and physical structure of the earth store the

hydrocarbons of the decomposed matter in geological deposits. These deposits

are initially identified by way of likely geological features.

Once a likely deposit area is identified the

first stage of exploration begins by exciting the substrate with seismic scale

stimulus. Seismic airgun surveys are the most common

technique used in ocean settings.

When

deposits are found and characterized, exploratory wells are sunk to determine

the production potential of the deposit and the quality of the product. In

deepwater settings exploratory wells are drilled from large stabilized floating

platforms.

At

the beginning of the exploration, caissons are built to mount a blowout

preventer (BOP) – a safety feature used in exploratory settings. Once a

deposit is determined to be suitably productive the BOP will be replaced by a

flow control system to prepare the well for production.

Fossil

fuel deposits are not just oil; rather they contain many other substances in

various concentrations depending on the nature of the deposit. It is not

uncommon for liquids (oil and brine), solids (sand, coal, shale), and gas

(methane, ethane, butane, CO2, nitrogen, etc) to all be part of the product

extracted out of the deposit. So the product coming out of the well is called

“multiphase” containing gas, liquids and solids.

This

multiphase product emerges from the wellhead typically under pressure. The flow

is mediated by a “choke” valve and distributed to a manifold.

Each

of these materials needs to be separated and handled appropriately. Waste water

is often injected back into the well, sand and solids are separated and dumped,

and gasses are either burned off, injected back into the well, or extracted and

utilized – depending on the proximity to gas processing facilities and

the environmental laws of the governing jurisdiction.

In

historic shallow water operations separation was done on platforms above water,

but increasingly these processes are occurring on the seafloor with seafloor

mounted separation and processing equipment.

Control

and monitoring of this equipment is accomplished through instrument packages

mounted on the various pieces of equipment, and by way both tethered (remotely

operated) and autonomous underwater vehicles (ROV’s an AUV’s

respectively). Communication to these instruments and vehicles takes place by

way of wired tethers as well as acoustic modems.

Noise

sources

Airguns:

Heretofore

the main noise concern in the fossil fuel industry was focused on seismic airgun surveys, whereby arrays of airguns

are towed across transects, exploding every ten to twenty seconds, sending a

seismic level impulse down into the water column and into the seafloor below.

While the signals from these arrays are focused

down, noise from the operations can be heard thousands of kilometers from the

source – echoing through entire ocean basins. As the surveys take place

in ever deeper water the reach of this noise will also increase.

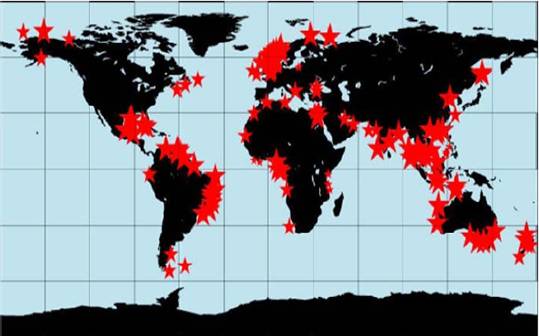

At

any given time there are 40 to 50 surveys happening globally.

Illustration courtesy of John Hildebrand

Exploratory

wells:

Once

likely deposits are located, a drilling site is prepared by installing a

wellhead “tree” and blow out preventer (BOP). This is then used to

seal the wellhead and guide the drilling bits and pipe into the earth. The

drill bits and pipe are the fed from the ocean surface from a stabilized

drilling platform such as the recent Deepwater Horizon.

These

platforms can have deck areas the size of a soccer field with displacements in

excess of 30,000 tons. In order to push miles of pipe into a well with accuracy

they are dynamically stabilized using six to eight “thrusters” that

can keep the drilling operation stable within 1 meter on the x, y, and z axes.

Thrusters

are large propellers powered by diesel-electric drives and depending on the sea

conditions during operation can generate significant noise from turbulence and

blade cavitation.

The

actual drilling noise is not substantial because any noise generated by drill

bit will be attenuated by the surrounding earth formation. Even when the pipes

“bang the hole” due to eccentricities in drilling actions, these

noises when monitored by geophones or seismometers will generate at most a

Richter scale value of 1 or less. (By way of comparison, a 40,000 lb. cargo

truck passing by might generate a Richter scale 4 “quake” –

in a logrhithmic scale 1,000 greater energy than a

Richter value of 1.)

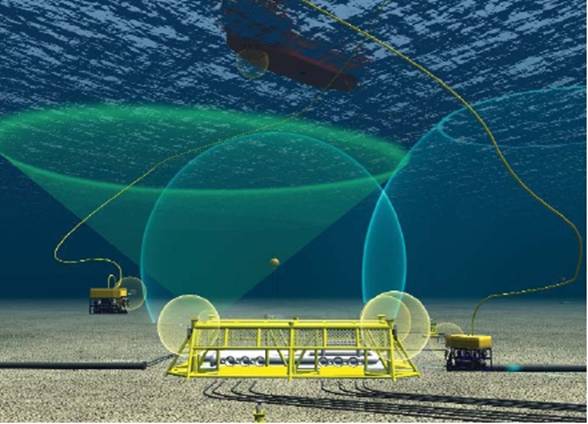

Increasingly

though equipment used in seafloor operations are fitted with telemetric

equipment communicating through multi-nodal networks for dynamic positioning

references, equipment identification, equipment condition monitoring, and

AUV/ROV communication.

Illustration: Nautronix

These acoustical modems operate in mid frequency

(1- 10 kHz) and high frequency (10-50 kHz) ranges, at typical source levels of

180dB re: 1 μPa with an operating range of 5-10

km. Noises in these frequency ranges and amplitudes have been correlated with

signals that aggravate beaked whales, porpoises, and dolphins, and may also have

negative impacts on some forage fish such as herring or shad.

Production:

Once

a well becomes productive the exploratory drilling apparatus’ are removed

and production piping and processing equipment are deployed. While this

processing has historically occurred on “Floating Production and Storage

Operations” (FPSO’s), increasingly as fields get out in deeper

water, production processing is being located on the sea floor – called

“subsea processing.”

Wellhead

pressures can be quite high – ½ psi per foot depth in water and an

additional 1 psi per foot depth in rock. (The recent BP Macondo

well was kicking out oil, gas, brine, and solids at an excess of 13,000 psi.)

From

the borehole the first control contact point for the product is the “choke”

– a valve that mediates the flow of product into the distribution tree.

Given the excessive pressures and hostile conditions these chokes are made of

tungsten carbide “tool steel.” Even so they wear out and need

periodic replacement. It is likely that the multiphase product flowing through

the choke and distribution tree will produce loud broad-band noise.

From

the distribution tree the product is piped to separators to separate the

valuable product from brine, sand, and solids. Depending on the composition of

the mix these separators are gravity, centrifugal, or product density driven.

In most cases separators form an expansion point in the product flow,

decreasing the net pressure of the product relative to flow, although if

possible pressures are kept high enough to push the product up to the surface.

In

the cases where the pressure is not adequate to overcome the column weight,

multistage pumps are deployed (driven by electrical motors). Additional pumps

are used to inject the brine and other waste products back into the deposit.

Each one of these pumps may not generate significant noise in and of itself,

but as operations expand across the seafloor cumulative noises from all of

these pumps will increase the noise floor of the marine habitat.

Illustration: FMC

Once the valued product is separated it is piped

to centralized storage and distribution operations. These

“tiebacks” can be 20 km from the wellhead and processing field and

can be floating platforms (FPSO’s) or in some cases located on shore.

Floating platforms will be tended by lighters, tankers, maintenance craft, and

crew transport vessels and helicopters, making these operations an area of high

noise concentrations.

Heretofore

no impact studies have been conducted to determine the effects that these new

noise fields have on the short or long term viability of marine life, but there

is a high probability that the impacts are not negligible.