Rong Bi (1, 2)

br0414@126.com

Kai Ming Li (1)

mmkmli@purdue.edu (to whom correspondence should be addressed)

Jun Chen (1)

junchen@purdue.edu

Zheng Shi Liu (2)

liuzhengshi@gmail.com

(1) Ray W. Herrick Laboratories

School of Mechanical Engineering

Purdue University

140 S. Martin Jischke Dr.

West Lafayette, IN 47907-2031, USA

(2) Hefei Univ. of Technology

193 Tunxi Road

Hefei, Anhui 230009, China

Popular version of paper 4pPA12

Presented Tuesday afternoon, May 24, 2011

161st ASA Meeting, Seattle, Washington

Imagine that you drive a car without a muffler along Main Street in a town. The roar of the internal combustion engine of your car can lead to an extremely loud noise at the end of the exhaust pipe. Even installing a less efficient muffler than the original one can cause your car to violate noise regulations that may earn you a citation from a police officer. Installing a properly designed muffler can reduce the roaring noise of the engine into a quiet purr.

A muffler, sometimes known as a silencer, plays an important role in our everyday life. It is a simple device that is widely used for noise control in industrial settings for reducing noise from pumps, fans, compressors, and, heating, ventilation and air conditioning (HVAC) systems. For the general public, the most commonly used mufflers are installed in our cars and motor cycles.

How to make your muffler work better? It depends on the choice of a suitable type of muffler. If you’ve ever looked inside a muffler, you’ll find its construction is deceptively simple. It consists of some tubes, baffles, chambers, and sometimes stuffed with fibrous materials. They are designed to reflect or absorb the sound generated by the engine at a certain frequency band. Although there are current interests to develop active noise control techniques, most mufflers continue to use the traditional passive methods.

A passive muffler is categorized as either a reactive or a dissipative muffler dependent on two different mechanisms used to reduce engine noise. A reactive muffler is designed to reflect sound back to the engine compartment by introducing area discontinuities (like expansion or contraction in a duct), branches (like resonator) and flow reversals. This design provides a good sound attenuation for low to moderate frequency bands.

A dissipative muffler uses fibrous materials such as fiberglass to attenuate noise by dissipating sound energy into heat through friction as exhaust air from the engine passes through the fibrous materials. Compared to a reactive muffler, the dissipative muffler shows a better acoustic performance over a wide frequency band for moderate to high frequency bands. Perforated tubes are usually introduced to retain absorbent material as well as guide the airflow in mufflers to avoid a large pressure drop. Sound energy can also be dissipated as exhaust air moves through the perforations.

In addition to the acoustic performance, another important consideration is how much backpressure the muffler produces when it is attached to the exhaust system. A high backpressure from the muffler can decrease the engine efficiency and increase the fuel consumption.

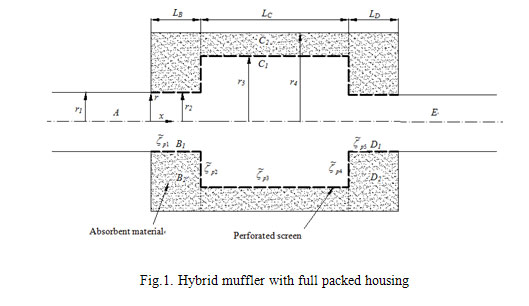

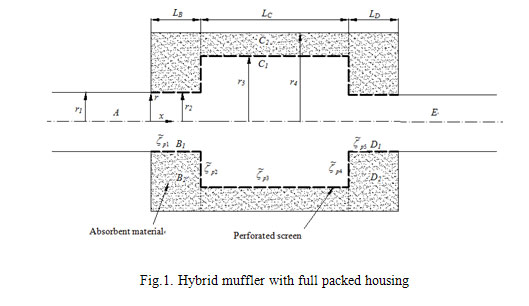

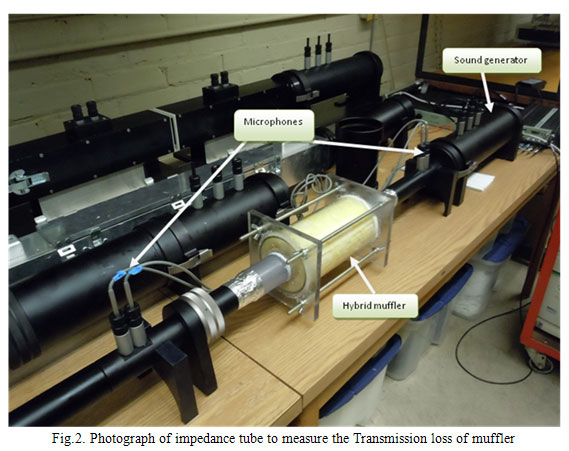

The muffler is a part of the exhaust system that is usually located under the car chassis and installed lengthwise along the vehicle. Due to the space limitation, there is a continual need to improve the acoustic performance of a muffler without changing its dimension. For this reason, researchers at Purdue University and Hefei University of Technology of China have been working together to look into an innovative way for improving the acoustic performance of mufflers without changing their sizes. A hybrid muffler, which combines the advantages of both reactive and dissipative types, is designed to provide a better sound attenuation in broader frequency range. Figure 1 shows a schematic diagram of the design of the hybrid muffler.

As shown in the schematic diagram of Fig. 1, the hybrid muffler combines an expansion chamber, perforated tubes and baffles, and, fibrous materials that are used to enhance the acoustic performance. Figure 2 shows an impedance tube that is used to measure the acoustic performance (Transmission loss) of a muffler. A plane sound-wave is generated by a loudspeaker on the right of impedance tube. The plane sound-waves created by the loudspeaker travel along the impedance tube to the inlet of the hybrid muffler. Some of the sound-wave reflects at the expansion and contraction of the duct. Some of the sound-wave goes into the fibrous material through the perforations of the tube in which some sound energy is dissipated as heat. Two microphones are mounted in upstream of the impedance tube and two other microphones are installed downstream of the impedance tube. These four microphones are used to measure the sound pressures at the inlet and outlet of the hybrid mufflers.

Several experiments were performed to determine the acoustic performance of different hybrid mufflers. Hybrid muffler 1 and hybrid muffler 2 are filled with low density and high-density fibrous materials respectively. Hybrid muffler 3, which is referred as a mixed impedance muffler, uses two different types of fibrous materials in the expansion chamber. From Fig. 3, we can see that all hybrid mufflers show better acoustic performances than a typical reactive muffler. Higher sound attenuations over broad frequency bands can be found in the hybrid mufflers. Particularly, the mixed impedance Hybrid muffler indicates a better acoustic performance than Hybrid Muffler 1 and Hybrid Muffler 2, which only uses a single fibrous material in the expansion chamber.

In the presentation, we shall discuss some theoretical results for the parametric studies of using different sound absorbent materials in the mixed impedance hybrid mufflers. By choosing different sound absorbent materials, we demonstrate that a specific hybrid muffler can be designed for sound reduction at any desired frequency bands.

One of the authors (BR) gratefully acknowledges the China Scholarship Council for the financial supports.