K. Anthony Hoover, FASA - thoover@mchinc.com

McKay Conant Hoover, Inc.

Acoustics & Media Systems Consultants

5655 Lindero Canyon Road, Suite 325

Westlake Village, CA 91362

Popular version of paper 1pAA1

Presented Monday afternoon, October 31, 2011

162nd ASA Meeting, San Diego, CA

Sound for Bollywood films is rarely recorded live in their sound stages, but is looped or added later, primarily because of poor ambient acoustics. Several new sound stages in Film City, Mumbai, India were begun, but construction ceased shortly after starting. After several years’ hiatus, the project was renewed with the directive that the existing fragmentary construction be used in the new design and as the foundation for subsequent construction, and with the goal of “Hollywood quality” acoustics. The design needed to address existing site conditions, encroaching hutments, concerns for local materials and methods, and uncertainty about how local contractors would actually implement the design.

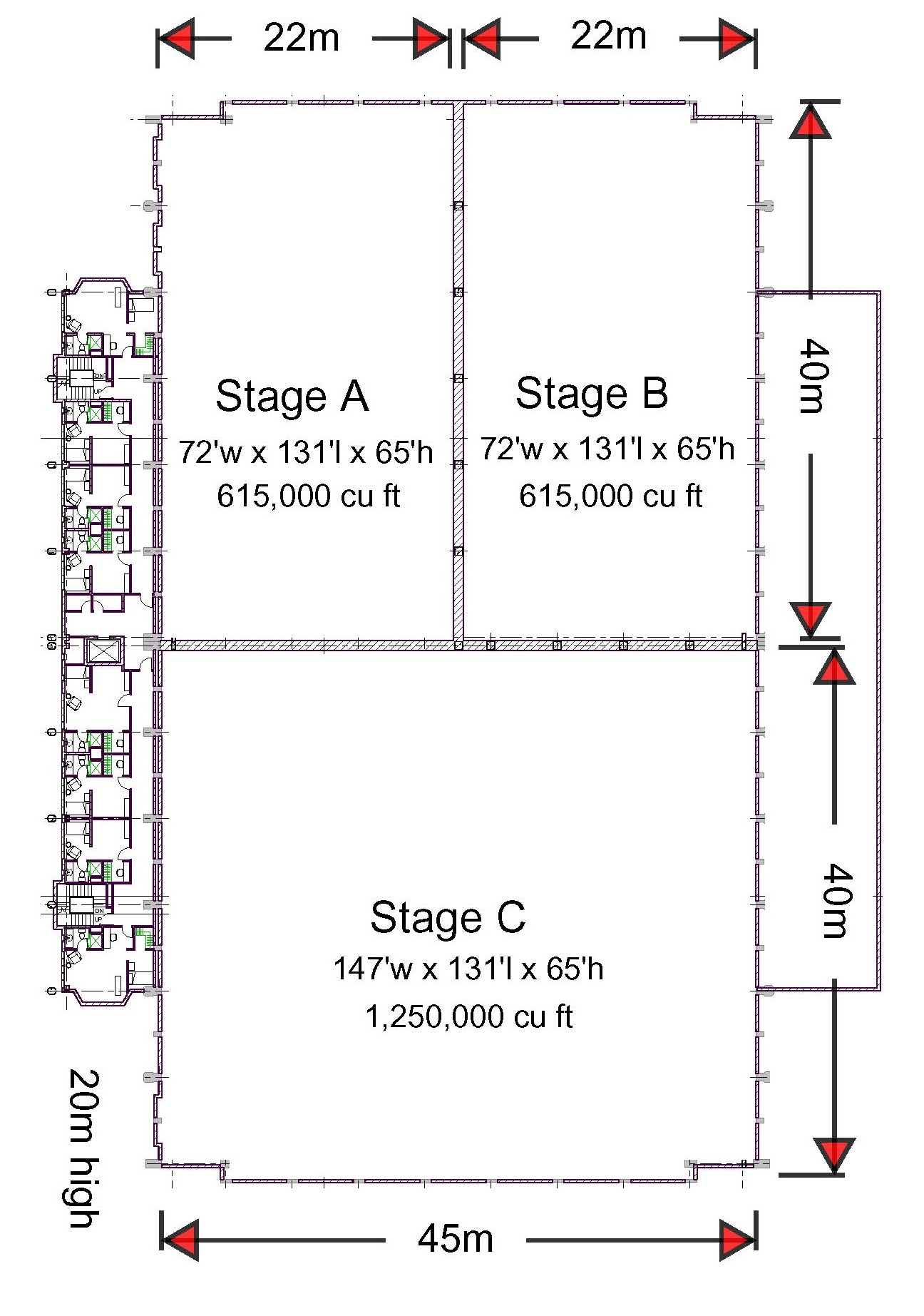

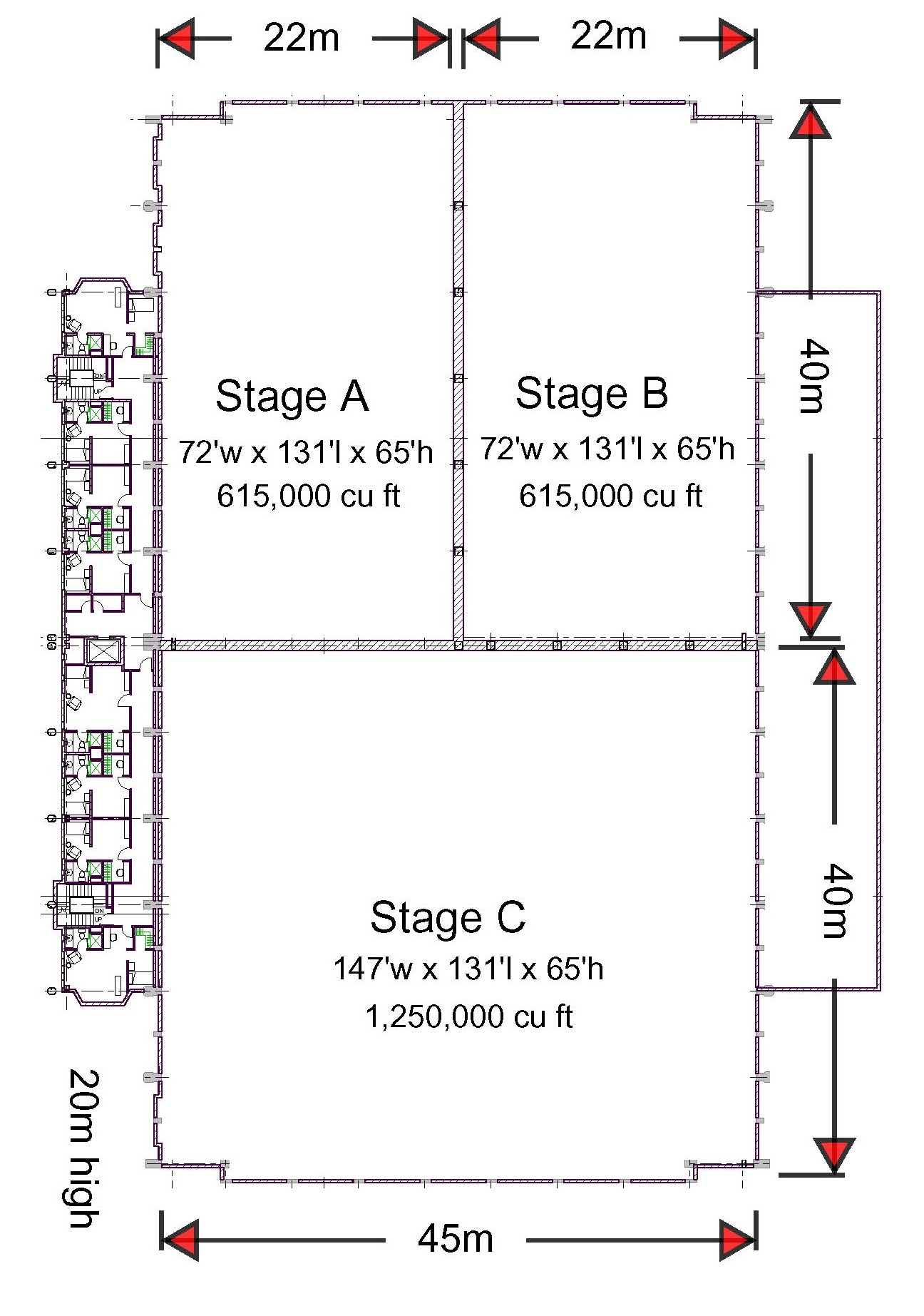

Figure 1 shows the plan of the sound stage facility, with three sound stages and ancillary support spaces. Approximate dimensions are included.

(Figure 1. Sound stage facility plan)

Post-construction inspection and testing in January 2011 concentrated on the three primary acoustical issues for any project, which are sound isolation (from outside to inside as well as between adjacent sound stages), mechanical system noise (HVAC background noise), and surface finish treatments (especially to provide sound absorption for minimal reverberation).

Sound isolation design was heavily influenced by the pre-existing foundations, using concrete structure infilled with locally-made clay bricks. Primary walls included an inner layer of clay brick and an outer layer of clay brick, separated by a wide airspace with glass fiber insulation in the cavity; this mass-airspace-mass construction is highly desirable, especially if there are no rigid connections between the masses. Figure 2 shows the concrete structure and portions of the outer wall infilled with clay brick, as well as the pre-existing construction upon which subsequent design and construction were to be based.

(Figure 2. Concrete structure and partially infilled outer wall)

Doors would be the weak links in sound isolation to the exterior, and truck doors needed to be very large to allow for trucks to load large equipment and sets. The design called for heavy inner and outer doors, separated by one-meter airspace. Figure 3 shows one of these truck doors, with the outer door closed and the inner door open.

(Figure 3. Truck doors, outer door closed and inner door open)

After proper adjustment to provide airtight seal upon door closure, the sound isolation was tested with several powerful loudspeakers generating loud levels of pink noise (sounding like a jet engine) outside of the doors. The doors were able to sufficiently block exterior noises, including diesel generators and ongoing construction of another sound stage on the other side of the access road.

Additionally, a cracker band (named after the firecrackers used along with drums and amplified instruments) from an adjacent hutment was hired to play outside the sound stages, since cracker bands play as often as several nights per week for various celebrations in the hutments. Figure 4 shows the cracker band and ongoing studio construction outside the finished studio building.

(Figure 4. Cracker band and ongoing construction outside of the completed sound stage facility)

The interior walls between sound stages were tested using loud pink noise, and were found to provide high levels of sound isolation. However, the testing showed that improved sound isolation could have been provided if the concrete structure did not connect the clay brick walls together, analogous to a string between two tin cans in a toy telephone. As had been discussed during the design phases, independent constructions or resilient connections would have benefitted the sound isolation between sound stages, but these were rejected by the clients as too expensive.

The HVAC system was measured to be extremely quiet, due to slow airflow velocities through very large ducts plus sound-absorptive linings inside the ductwork. In fact, the HVAC system was essentially inaudible, and was measured to be only slightly louder than the quietest sounds levels that people can hear.

The remaining concern was the amount of reverberation inside the sound stages, which is primarily determined by the efficiency and extent of sound-absorptive finishes on the walls and ceiling. The design was to install thick glass fiber insulation on almost all wall and ceiling surfaces; in turn, the glass fiber was to be covered by a sound-transparent fabric to prevent the glass fiber from shedding, and colored black to prevent light reflections. Figure 5 shows the interior of Stage B with a large video screen. Note that the walls are covered with the black sound-absorptive treatment.

(Figure 5. Stage B with large video screen)

Figure 6 shows the (yellow) glass fiber with (black) fabric facing. There is also an open wire mesh at lower elevations to provide some additional protection and durability for this treatment.

(Figure 6. Sound absorptive treatment)

The reverberation times were measured to be short and dry, so that recorded sounds would not have an audible reverberant character such as might otherwise be expected in enormous rooms like these sound studios. Dry sound is desirable so that editors can add any kind of sound effects of their choosing during post production. Excessively reverberant recordings are very difficult to correct or modify later, whereas reverb, echoes, or other effects are quite simple and commonly added in post production.

However, the reverberation times were not quite as dry as had been designed. The data showed that the installed black fabric finish was not as transparent to sound as the finish that had been specified, resulting in some of the sound reflecting off the fabric instead of transmitting into the glass fiber where it would be absorbed. Their future sound stages will benefit from more transparent facings.

These sound stages are among the finest in Bollywood, finally allowing for live audio recording. All of the challenges of an international project notwithstanding, both the client and the end users acknowledge and recognize that the acoustics in these sound stages are far superior to others in India, and are on par with similar venues around Hollywood.