Wind Turbine Blade Health Monitoring using Acoustic Beamforming Techniques

Christopher Niezrecki – Christopher_Niezrecki@uml.edu

Peyman Poozesh – Peyman_poozesh@student.uml.edu

University of Massachusetts Lowell

Structural Dynamics and Acoustic Systems Laboratory

Lowell, MA 01854

Kai Aizawa – kai_aizawa@camal.mech.chuo-u.ac.jp?

Chuo University

Tokyo, Japan

Gunnar Heilmann - heilmann@gfaitech.de

gfai tech GmbH

12489 Berlin-Adlershof, Germany

Popular version of paper 4pSP5

Presented Thursday afternoon, May 4, 2014

167th ASA Meeting, Providence

---------------------------------

Wind turbines operate autonomously and can possess reliability issues attributed to manufacturing defects, fatigue failure, or extreme weather events. In particular, wind turbine blades can suffer from leading and trailing edge splits, holes, or cracks that can lead to blade failure and loss of energy revenue generation. Poor reliability and damage leads to excessive repair costs that raise the cost of wind generated energy. In order to help identify damage, several approaches have been used to detect cracks in wind turbine blades; however most of these methods require transducers to be mounted on the turbine blades, are not effective, or require visual inspection.

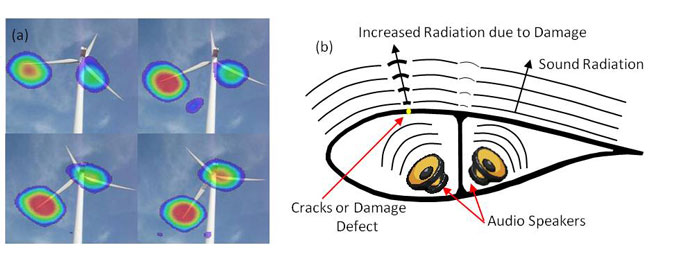

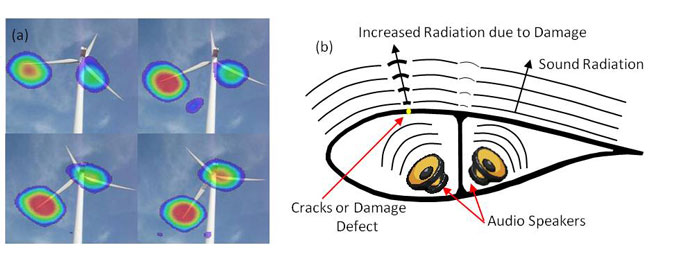

Although wind turbine environmental noise has historically been of great interest [1-3], only recently has beamforming been used to identify the sound radiated from operating wind turbines for structural health monitoring. Figure 1a shows an example of beamforming performed on a wind turbine in operation [4] where the primary source of sound characterized is that caused by the flow-induced noise.

Acoustic beamforming is a method for processing microphone array data to produce visual images that represent the distribution of the acoustic source radiation and relative strength [5]. The signals received by the microphones are processed to reveal the sound source location and are usually mapped on a planar surface [6]. Because the distance from each source to each microphone in the array varies, all the signals will have a relative time delay. The pressure can be computed at any point in front of the array, taking into account the time delay corresponding to the propagation distance. Because the original sound signal is estimated by adding time delay and summing the signals, this method is called “Delay and Sum” beamforming which is performed in time domain. There are several methods also performed in the frequency domain but are closely related to the time domain methods [7].

This paper proposes a new methodology of the wind turbine non-contact health monitoring using acoustic beamforming techniques. By mounting an audio speaker inside of the wind turbine blade, it may be possible to detect cracks or damage within the structure by observing the sound radiated from the blade as shown in Figure 1b.

Figure 1. a) Example of beamforming performed on 52 m diameter, 65 m high, Gamesa wind turbine during rotation [4]; b) Cross section of a typical wind turbine blade with audio speakers ensonifying the internal cavities. Cracks reveal themselves as changes to the external sound radiation pattern.

It has been proposed that structural damage or cracks on the surface of a composite wind turbine blade may lead to the changes in the sound radiation characteristics of the structure. Within our research, we have conducted preliminary tests on a composite box and a section of a wind turbine blade containing holes of differing dimensions and a line crack. The damaged areas were used to verify the approach has merit. It was shown that acoustic beamforming can be used to readily identify the location of the damage in the composite box and wind turbine blade.

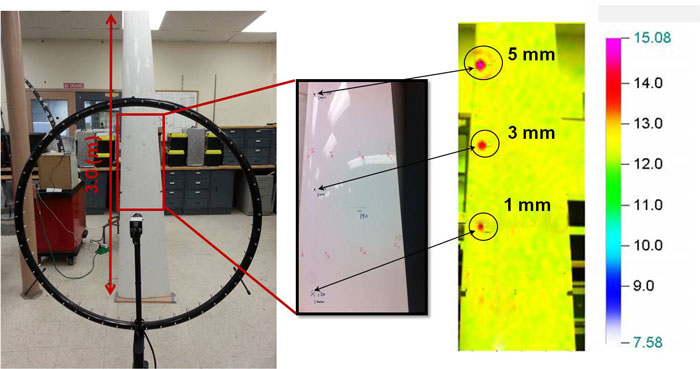

For the experiment, we used a ring array that had 48 microphones (as shown in Figure 2) to measure the sound radiation of a composite box and a section of a wind turbine blade, both of which had an audio speaker placed inside. The results on the composite box clearly reveal that the beamforming technique can identify the line crack and three holes with different diameters as shown in Figure 2c.

Figure 2. a) microphone array; b) array with composite box; c) acoustic beamforming result of box revealing the location of the 1mm, 3mm, and 5mm diameter holes and the line crack.

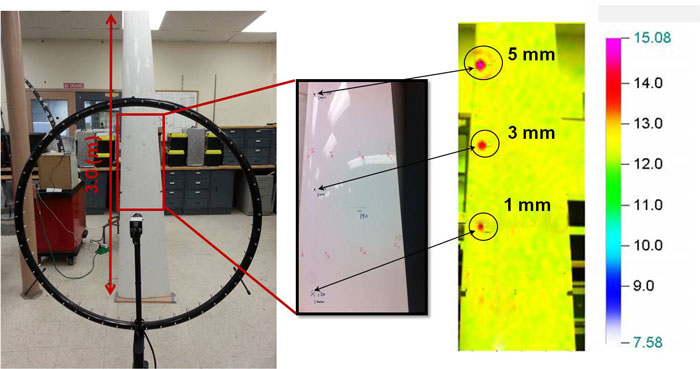

A similar beamforming scan of a 3-m section of a composite wind turbine blade was performed as shown in Figure 3. The image reveals that holes in the blade surface as small as 1 mm in diameter can be easily detected.

Figure 3. Ring microphone array in the foreground with a wind turbine blade section in the background (left); acoustic map of the sound radiated from the blade with holes in the blade (right).

The preliminary results shown in Figures 2 and 3 indicate that acoustic beamforming used in conjunction with internal audio excitation is an effective way to detect structural damage in composite wind turbine blades.

References:

[1] Pedersen, E., van den Berg, F., Bakker, R., and Bouma, J., “Response to noise from modern wind farms in The Netherlands,” J. Acoust. Soc. Am. Volume 126, Issue 2, pp. 634-643, Aug., 2009.

[2] Paul, B., Martinez, R., Thompson, D., and Uhlman, J., “Prediction methodologies for tonal and broadband noise from horizontal-axis wind turbines,” J. Acoust. Soc. Am. Volume 125, Issue 4, pp. 2624-2624, Apr., 2009.

[3] Leroux, M., Gervais, Y., Borée, J., and Ménoret, A., “Experimental investigation of wind turbine noise,” J. Acoust. Soc. Am. Volume 123, Issue 5, pp. 3688-3688, May, 2008.

[4] Zheng, Z. and Wei, L., “Development of a Real Time Noise Source Identification System using Reconfigurable Field Programmable Gate Array Technology” Inter-Noise 2008, Shanghai, China, October 26-29, 2008.

[5] Dougherty, R. P., “WHAT IS BEAMFORMING?”, Berlin Beamforming Conference (BeBeC), Berlin, Germany, February 19-20, 2008.

[6] Sijtsma, P., “Experimental techniques for identification and characterization of noise sources”, National Aerospace Laboratory, NLR-TP-2004-165, 2004.

[7] Michel, U., “History of acoustic beamforming”, Berlin Beamforming Conference (BeBeC), Berlin, Germany, November 2006.