Dimitri M. Donskoy - ddonskoy@stevens-tech.edu

Alexander E. Ekimov, Nikolay Sedunov and Michael Tsionskiy

Stevens Institute of Technology

Hoboken, NJ 07030

201-216-5316

Popular version of paper 4pPA2

Presented Thursday Afternoon, December 6, 2001

142nd ASA Meeting, Fort Lauderdale, FL

The most commonly used devices for land mine detection are metal detectors that work by measuring the disturbance of an emitted electromagnetic field caused by the presence of metallic objects in the ground. For ferromagnetic objects, magnetometers are employed. These sensors measure the disturbance of the earth's natural electromagnetic field. Neither of these types of detectors can differentiate a mine from metallic debris; this leads to up to 1000 false alarms for each real mine. In addition, most modern antipersonnel mines are made out of plastic or wood with very few metal parts in them, so the metal detectors cannot detect them. Newer methods conceived to detect mines involve ground-penetrating radar, infrared imaging, X-ray backscattering, thermal neutron activation, and some others. Most of these methods rely on imaging and very often cannot differentiate a mine from rocks and other debris. The drawbacks of the other non-imaging techniques, such as thermal neutron activation, apart from system complexity, are the limited depth of penetration and the potential environmental and health danger.

Acoustic methods of detecting mines were always a primary approach for underwater mine detection. However, earlier attempts to use acoustic energy for land mine detection were not successful due to a number of deficiencies. One method, House and Pape [1], identifies a buried object by viewing the images of the acoustic energy reflected from the soil and, therefore, is unable to differentiate a mine from debris with similar acoustic reflectivity. Other methods, Rogers and Don [2] and Caulfield [3], are based on the comparison of a reflected acoustic signal with a reference signal in order to provide detection of the object. The difference between these two signals indicates the presence of an object. The drawback of these methods is that any variations in the physical properties of the ground (density, porosity, moisture content, etc.) as well as the presence of non-target objects (rocks, tree roots, debris, etc.) creates a difference from the reference signal and, consequently, lead to the high false alarm rates. Recent advances in sound and vibration measurement techniques and signal processing have opened new possibilities for land mine detection using seismic/acoustic energy, Donskoy [4-6], Sabatier and Xiang [7,8], Scott [9,10].

The essence of the seismic/acoustic approach is to excite low frequency (typically below 1000 Hz) vibration of a soil and measure soil surface "vibration signature" above the buried mine using remote sensors. Soil vibration is excited by air-borne (acoustic) or solid-borne (seismic) waves. Remote sensing is achieved with laser-doppler vibrometers (Sabatier, Donskoy) or microwave vibrometers (Scott, Donskoy). Fig.1 shows example of such an approach: the image of the surface vibration obtained with a scanning laser-doppler vibrometer reveals a buried plastic mine. .

Understanding and correct processing of mine's "vibrating signatures"

is a key element of sesmo-acoustic detection. At Stevens Institute we have developed

innovative landmine detection and discrimination technique by analyzing "nonlinear

distortions" of the soil vibration due to buried mine. The simple way to

explain "nonlinear distortions" it is to bring a tuning fork in contact

with any solid object: the pure tone of the fork will be noticeably "distorted"

then fork "bouncing" against the object. Mine casing behaves like

a tuning fork in contact with the surrounding soil: a pure tone of exciting

vibration is distorted by the "bouncing effect" on the mine-soil interface.

This effect does not depend on mine casing material and is observed for metal,

plastic, and wooden mines. On the other hand, solid objects (false targets),

such as rocks, tree roots, shrapnel, etc. do not produce any noticeable distortion,

because they are very stiff and can not be as easily excited (vibrated) as much

more compliant mine casing.

Therefore, the nonlinear distortion effect is very distinguishable and discriminative

with respect to mines and can be employed as an effective detection technique

having high probability of detection with low false alarm rate. Comprehensive

model of mine/soil interaction supported by numerous laboratory tests validated

this effect of "nonlinear vibration signature" of land mines.

In August 2000 at the US Army testing ground we measured dynamic (vibration)

properties of over 50 live antipersonnel and antitank mines (plastic, metal,

and wooden) (see Fig.2). These measurements yielded a unique database of acoustic

signatures of the mines, which, in combination with the developed model, helps

greatly enhance detection performance.

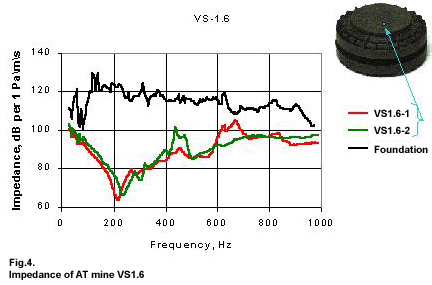

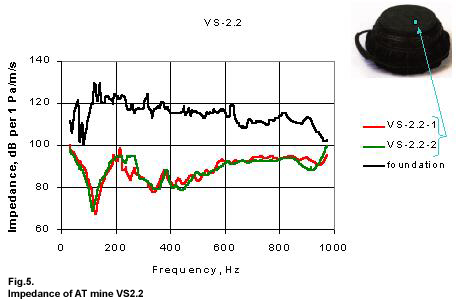

One of the most important quantitative characteristics of mine response to external

vibration is so called mechanical impedance. Fig.3- 5 show typical impedances

of antitank (AT) mines: the lower the impedance, the greater the mine vibration

response and, hence, the more pronounced the bouncing (nonlinear) effect. Remarkably,

most of the AT mines have minimum impedance in the relatively narrow frequency

range between 100 Hz and 400 Hz. The minimum impedances of antipersonnel (AP)

mines are spread over wider frequency range (up to 1000 Hz).

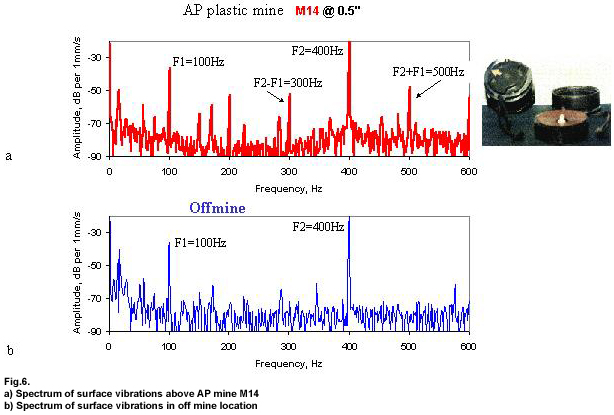

Knowing the most responsive frequency range from the impedance measurements,

the nonlinear distortion effect from respective buried mine can be evaluated

by applying vibration at two frequencies (f1 and f2) and measuring the nonlinear

response at the intermodulation frequencies f1 ± f2 . Fig.6 illustrates

this approach. In this test, the bi-harmonic signal with the frequencies f1

= 100 Hz and f2 = 400 Hz was broadcast toward soil. The spectrum of the soil

surface vibration above the buried AP mine M14 (Fig.6a) clearly demonstrates

the result of nonlinear intermodulation (frequency components f1 ± f2)

due to the buried mine. There are no such components at off mine locations (Fig.6b)

or above buried false targets such as rocks (not shown).

In June 2001, we successfully conducted field test of the nonlinear seismo-acoustic detection technique at the US Army testing ground. Plastic antitank mines (M19, VS1.6, VS2.2) were confidently detected at 5 in. depth in both gravel and dirt testing lanes. Plastic antipersonnel mines (M14, VS50, TS50) were also confidently detected up to 2 in. depth in both gravel and dirt lanes. Mine M14 one of the smallest mines which is very difficult to detect.

The test proved that the nonlinear seismo-acoustic detection algorithm is very sensitive to AT and AP mines, while completely insensitive to false targets, such as rocks, chunks of metal or wood, thus promising to deliver high probability of detection with low false alarm rate.

The full paper is submitted for publication to the Journal of the Acoustical

Society of America.

ACKNOWLEDGMENTS

This material is based upon work supported by the U.S.Army Research Office and Night Vision and Electronic Sensors Directorate (part of the U.S. Army Communications-Electronics Command). The authors thank Dr. Tomas Witten and Dr. Charles Cannon for their valuable comments and support of this work. The authors also thank to Mr. John Fasulo and his colleagues for their assistance in conducting field tests.

REFERENCES