Greg Swift - swift@lanl.gov

Los Alamos National Laboratory

Los Alamos, NM

Special Lay-Language Paper for

ASA's 75th Anniversary Meeting

May 2004

Thermoacoustics is the study of things that involve both acoustics and thermodynamics-in

other words, the study of things that involve both sound waves and the conversion

of one form of energy into another, such as heat into motion. When a sound wave

travels through air or any other gas, it creates pressure and motion oscillations

in the gas. However, the temperature of the gas oscillates as well. When the

sound travels through gas in small channels, heat also flows to and from the

channel walls. The combination of all such oscillations produces a rich variety

of "thermoacoustic" effects.

Research in thermoacoustics began with simple curiosity about the oscillating heat exchanged between sound waves and solid boundaries. These interactions are too small to be obvious in the sound in air with which we communicate every day. However, in intense sound waves in pressurized gases, thermoacoustics can be harnessed to produce powerful engines, pulsating combustion, heat pumps, refrigerators, and mixture separators. Hence, current thermoacoustics research is often motivated by the desire to create new technology for the energy industry that is as simple and reliable as sound waves themselves. Web searches of "pulsating combustion" and "thermoacoustics" will reveal some of the current commercial development activities and many academic groups studying thermoacoustic phenomena at a fundamental level.

A century ago, Lord Rayleigh understood the most important characteristic of spontaneous heat-driven acoustic oscillations: "If heat be given to the air at the moment of greatest [density] or be taken from it at the moment of greatest rarefaction, the vibration is encouraged." Today, the high-intensity thermoacoustic engines based on this simple principle can convert high-temperature heat (such as from burning a fuel) to acoustic power with an efficiency comparable to that with which internal-combustion engines convert heat to mechanical power.

Similar oscillations can also occur whenever combustion takes place in a cavity. The oscillations occur spontaneously if the combustion progresses more rapidly or efficiently during the compression phase of the pressure oscillation than during the rarefaction phase. Such oscillations must be suppressed in rockets to prevent catastrophic damage, but they are deliberately encouraged in some gas-fired residential furnaces and hot-water heaters to improve their efficiency.

Watt for watt, acoustic power is as valuable as electrical power or mechanical power. Converting acoustic power from a thermoacoustic engine into mechanical power or electrical power involves the use of moving pistons or magnets, which might at first seem to compromise the simplicity and reliability inherent in the sound waves themselves. However, modern "linear alternators" can convert acoustic power to electricity without rubbing parts, without the need for lubrication. Flexing guides allow the pistons of such alternators to oscillate in their cylinders without touching the cylinder walls, and the magnets carried by the pistons oscillate through coils of copper wire without touching them to generate electricity.

Acoustic power generated by a thermoacoustic engine can also be used to drive a thermoacoustic refrigerator, avoiding all use of moving parts when a heat-driven refrigerator is called for. Within the passages of a thermoacoustic refrigerator, Rayleigh's criterion for spontaneous oscillations is not satisfied-acoustic power is consumed, not created. However, the interconnected oscillations of gas motion, temperature, and heat flow in the sound wave are coordinated so that heat is absorbed from a load at low temperature and waste heat is rejected to a sink at higher temperature. The first thermoacoustic refrigerator was built in the early 1980s, and its offspring are still under study today.

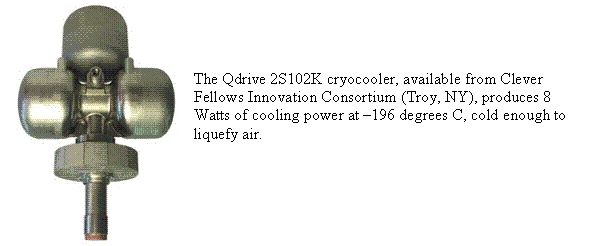

A close cousin of the thermoacoustic refrigerator, the "pulse-tube refrigerator"

has been the most actively developed cryogenic-refrigeration technology of the

past two decades. This thread of the story began with the accidental discovery

and subsequent investigation of cooling associated with pulses of oscillating

pressure applied to one end of a pipe that was closed at the other end. The

phenomenon shares a theoretical foundation with the thermoacoustic refrigerator,

although their relationship was not recognized at first. Subsequent improvements

have led to a hybrid thermoacoustic-Stirling cryogenic refrigerator known today

as the "orifice pulse-tube refrigerator." These refrigerators are

available from several companies, and are used for cooling infrared sensors

on satellites as well as on Earth.

|

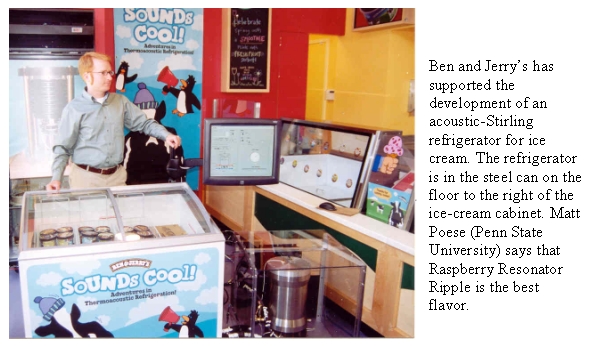

Stirling engines and refrigerators were invented in the early 18th century,

with the engines representing an alternative to steam engines. Crankshafts,

multiple pistons, and other moving parts seemed at first to be essential. However,

an acoustic perspective came to Stirling engines in the 1980s when it was realized

that the relative timing between pressure and motion oscillations in them is

that of a traveling acoustic wave: The peaks in the pressure occur at the same

times that the velocity peaks in one direction, and the valleys in the pressure

occur at the same times that the velocity peaks in the opposite direction. In

the late 1990s, acoustic versions of Stirling refrigerators and engines were

first demonstrated, with no pistons or other moving parts, and already today

a powerful, efficient combination of acoustic-Stirling engine and pulse tube

refrigerator has demonstrated efficient combustion-powered cryogenic refrigeration,

and an electrically driven acoustic-Stirling refrigerator has kept Ben and Jerry's

ice cream cold!

| This combustion-powered thermoacoustic natural gas liquefier stands at Praxair, Inc., in Denver Colorado, and is much taller than 6-foot-2 John Wollan beside it. A natural-gas fired burner supplies heat to an acoustic-Stirling engine, which produces acoustic power to drive three pulse tube refrigerators. Cooling natural gas to -133 degrees C condenses it from gas to liquid, so that it can be easily transported where pipelines don't exist. |  |

|

|