R. N. Miles1- miles@binghamton.edu

W. Cui1, Q. Su1 , R. Wu1, L. Tan1, Y. Liu1, S. Jones1, V. Mohnankrishnaswamy1, T. Strait1, W. Butler1, D. Dibernardo1, F. L. Degertekin2, B. Bicen2, K. Jeelani2, W. Lee2, S. Qureshi2

1Department of Mechanical Engineering

P.O. 6000

State University of New York

Binghamton, NY 13902-6000

2G. W. Woodruff School of Mechanical Engineering

Georgia Institute of Technology

801 Ferst Dr. NW

Atlanta, GA 30332-0405

Popular version of paper 3aEA7

Presented Thursday Morning, November 30, 2006

4th ASA/ASJ Joint Meeting, Honolulu, HI

An extremely common complaint of hearing aid users is that they have great difficulty understanding speech in noisy environments. The use of directional microphones has shown considerable promise for addressing this problem. A number of clinical studies of the hearing impaired have demonstrated improvements in speech intelligibility in noise from the use of directional microphones. While advances in directional microphone technology are of great interest, the most recent revolutionary change in microphone construction was the advent of the commercially viable electret over thirty years ago; the sensor still consists of a metalized pressure-sensitive membrane placed near an electrode. In contrast to the modest advances in microphone technology, our ability to process signals has exploded through the advent of low-power digital signal processors and Sigma-Delta analog-to-digital conversion. Our processing technology has outpaced our acoustic transducer technology. The development of improved directional microphone technologies coupled with improved signal processing algorithms will result in a demonstrable improvement in the lives of the hearing impaired.

Conventional microphones often consist of a thin diaphragm along with a backplate electrode positioned in parallel at a small distance away. This permits the detection of the motion of the diaphragm through the capacitance change between the diaphragm and the backplate. There are a few limitations of this configuration. First, the viscous damping caused by the air between the diaphragm and the backplate can have a significant negative impact on the response. Secondly, the signal to noise ratio is negatively influenced by the electronic noise associated with the capacitive sensing and the thermal noise associated with the passive damping. Thirdly, while the electrical sensitivity is proportional to the bias voltage, if the voltage exceeds a critical value the attractive force associated with this bias voltage will cause the diaphragm to collapse against the backplate.

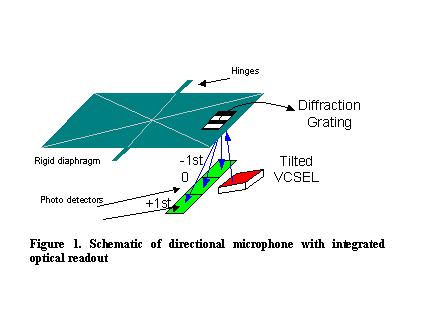

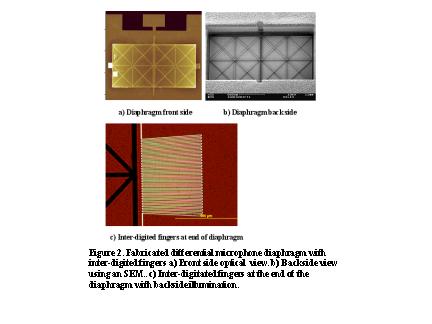

The novel biomimetic differential microphone diaphragm developed in this study, shown in Fig. 1, is based on a mechanical model of the ears of the parasitoid fly, Ormia ochracea. The diaphragm is combined with an optical sensing scheme to provide electronic readout of the diaphragm deflection with a minimum of electrical and thermal noise. The 1mm by 2mm diaphragm is supported at only two pivot points at the middle and reinforced with stiffening ribs. The thickness of the diaphragm is 2 m. Inter-digitated fingers, shown in fig 2, are incorporated at the two ends of the diaphragm, the locations with maximum deflection as the diaphragm rocks about the hinges in response to sound. The dimensions of this structure have been determined by a detailed finite element-based optimization. This structure provides a highly compliant differential microphone that responds to the differences in pressure on the two sides of the diaphragm that are separated by the hinges at the center.

The optical detection method is based on a phase-sensitive grating structure, where the intensity of reflected diffraction orders is monitored as the displacement signal. Using vertical cavity surface emitting lasers (VCSELs) as the light source and integrating photodetection electronics as shown in Fig. 1, the overall volume of the interferometer can be reduced to the cubic millimeter level.

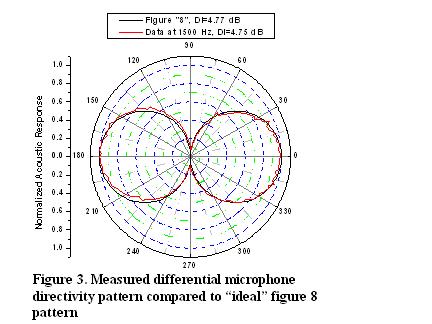

The measured acoustic directionality of the microphone diaphragm is shown in fig. 3. This figure shows a polar plot of the amplitude of the output of the microphone for various angles of incidence of the sound. The microphone is most sensitive to sound incident from either zero or 180 degrees least sensitive to sounds incident from angles of either 90 or 270 degrees. The figure shows that the microphone diaphragm's response is extremely close to the expected figure eight directivity pattern of an "ideal" differential microphone.

For more information about this work, please visit: http://www.wso.binghamton.edu/Angel/frameIndex.htm (click on: Faculty Research, then Microacoustic Sensors Laboratory)

Inquiries may be directed to:

Gail C. Glover

Director of Media Relations

Binghamton University

PO Box 6000

Binghamton, NY 13902

cell: 607-648-3593

office: 607-777-2174

fax: 607-777-4984