Skull Flexure from Blast Waves: a Mechanism for Brain Injury with Implications for Helmet Design*

William C. Moss - wmoss@llnl.gov

Michael J. King

Lawrence Livermore National Laboratory

7000 East Ave.

Livermore, CA 94551

Eric G. Blackman

Dept. of Physics and Astronomy

University of Rochester

Rochester, NY 14627

Popular version of paper 3pBB5

Presented Wednesday afternoon, May 20, 2009

157th ASA Meeting, Portland, OR

Traumatic brain injury [TBI] results from mechanical forces in the brain, often without skull fracture, and causes complex, long lasting symptoms. TBI in the civilian population is usually caused by head impacts resulting from motor vehicle and sports accidents or severe falls. TBI has also emerged in military combat personnel who survive explosive attacks. Consequently, there is an urgent need to understand the mechanisms by which explosive blasts cause TBI, so that improved protective equipment (such as helmets) can be designed and injured soldiers can be diagnosed more effectively.

Extensive studies have shown that impact-induced TBI [ITBI] is related to the acceleration of the head. By contrast, the damage-producing mechanisms for blast-induced TBI [BTBI] are not well understood. Although several mechanisms have been proposed for how a blast can damage the brain, blast-induced deformation of the skull has surprisingly been neglected, perhaps due to the perception that the hard skull protects the brain from non-lethal blast waves. Here we show via computer simulations that direct action of the blast wave on the head causes skull flexure, producing mechanical forces in brain tissue comparable to those in an injury-inducing impact, even at non-lethal blast pressures as low as 1 atmosphere above ambient pressure.

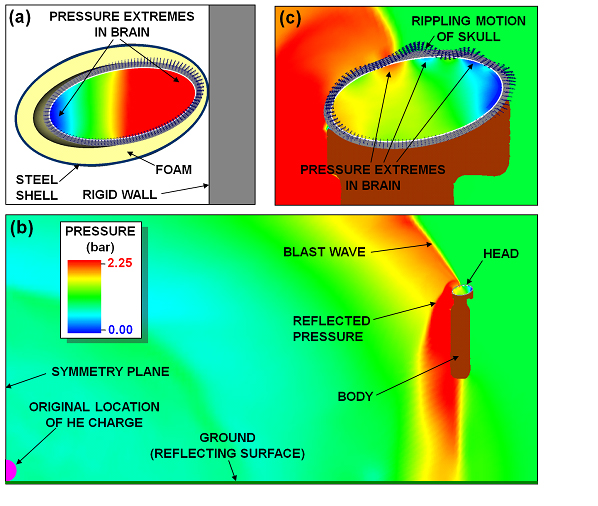

Figure 1 shows our blast simulation geometry. The explosive charge size and standoff distance were chosen to generate a non-lethal blast wave according to military injury thresholds. The skull is modeled as a hollow elastic ellipsoid that contains a layer of cerebral spinal fluid [CSF] and a viscoelastic material representing the brain. A simplified face (with no lower jaw), neck, and body are included to capture blast-induced accelerations accurately and to appropriately shield the bottom of the braincase from direct interaction with the blast wave. Anatomical details such as skull thickness variations, grey/white matter distinction, ventricles, etc. are not included. Although these features will affect the detailed mechanical response needed to predict specific medical traumas, our simplified model is sufficient to reveal the general mechanisms by which blasts load the brain. It also provides a means of exploring protective strategies: a helmet that reduces the magnitude of the loads in the brain would necessarily reduce TBI.

|

Figure 2 highlights the differences between impacts and blasts. Figure 2a shows a simulation of an impact that would cause injury according to automotive injury metrics. During this impact, the head undergoes ~200 G’s of acceleration for about 2 milliseconds. The brain collides with the decelerating skull and develops large pressures at the impact site and tensions at the opposite location. The brain oscillates until the impact energy is dissipated.

|

| Figure 2. Pressure and skull motion for impact and blast simulations: (a) Angled impact simulation. A “helmet” consisting of steel and crushable foam is used to control the severity of the impact. (b) Blast wave propagating past the simulated victim 5.6 milliseconds after detonation. (c) Expanded view of the head as the blast wave passes over it. Inward and outward rippling of the skull cause pressure extrema in the brain. The skull deflections are ~50 microns. |

Blast simulation results are shown in Figures 2b,c and indicate dramatically different loads on the brain than those from impact. Figure 2b shows the shock wave from the blast transiting the body. The blast wave transits in less than a millisecond at a speed of ~450 meters/second, with a pressure of 1 atmosphere in excess of the ambient pressure. It induces ~80 G’s of bulk acceleration for 0.3 milliseconds, which is less than half of the acceleration acting over a much shorter time, than that generated by the impact in Figure 2a. Figure 2c shows an expanded view of the head with pressure contours in the air and brain, and velocity vectors in the skull. The moving pressure wave generates flexural ripples in the skull, which cause regions of large pressure and tension in the brain. Despite the lower acceleration, the loads in the brain caused by the blast are as severe as those from the impact simulation, and the pressure gradients (which can cause shearing and tearing) are much larger (several atmospheres/centimeter), because the extremes are closer together.

Because soldiers wear helmets, it has been suggested that their heads are protected from shock waves caused by a blast. The primary function of a soldier’s helmet is to provide protection from bullets, shrapnel, and fragments, but it is not obvious how well it protects against blast. Consequently, we conducted additional simulations to investigate this question. We simulated a simplified helmet consisting of a hemi-ellipsoidal Kevlar shell, coupled to the head with one of two different suspension systems used in current helmets: a nylon web suspension system and foam pads.

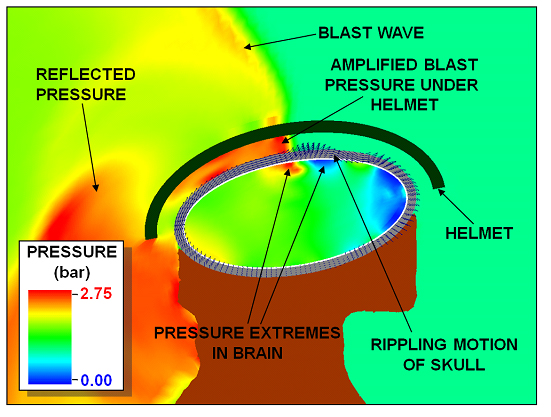

Figure 3 is from a blast simulation of a helmet with the webbed suspension. Ballistic standards require a 1.3 centimeter gap between the helmet and the head in order to adequately protect against bullets and shrapnel. Because a webbed suspension does not block this gap, the blast wave can wash under the helmet, and the shape of the space between the helmet and the head actually amplifies the blast wave. The resulting pressures on the skull under the helmet exceed those outside the helmet (or those that would occur in the absence of a helmet). Hence a webbed suspension does not appear to protect the head from blast waves.

|

| Figure 3. Blasts can interact with helmets and suspension systems in unanticipated ways: Amplification of the blast pressure and loads on the head due to “underwash” for a helmet without foam pads. |

Foam pads do prevent the blast wave from washing under the helmet, because they fill the space between the helmet and the head. However, helmet accelerations and deformations can be transferred to the skull and brain through the foam, which generally stiffens at high loading rates. Even “optimal” foams that minimize this load transfer can only provide partial protection, because the helmet does not cover enough of the head at the back and sides to completely prevent skull flexure.

If skull flexure proves to be a primary mechanism for BTBI, then there are significant implications for protective equipment design. An effective mitigation strategy would be to deny the blast wave access to the airspace under the helmet, and then either incorporate rigidity into the helmet shell, or design the helmet suspension system so that the flexure of the helmet is not transferred to the skull, while protecting against accelerations from blasts or impacts.

*This work performed under the auspices of the U.S. Department of Energy by Lawrence Livermore National Laboratory under Contract DE-AC52-07NA27344.

This document was prepared as an account of work sponsored by an agency of the United States government. Neither the United States government nor Lawrence Livermore National Security, LLC, nor any of their employees makes any warranty, expressed or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States government or Lawrence Livermore National Security, LLC. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States government or Lawrence Livermore National Security, LLC, and shall not be used for advertising or product endorsement purposes.