2pSA9 – Acoustic transients from the impact force excitation of beams and wind chimes

Peter Stepanishen, steppipr@uri.edu

University of Rhode Island

Department of Ocean Engineering

Narragansett, RI 02871

Popular version of paper 2pSA9

Presented on Tuesday December 3, 2019

178th ASA Meeting, San Diego, CA

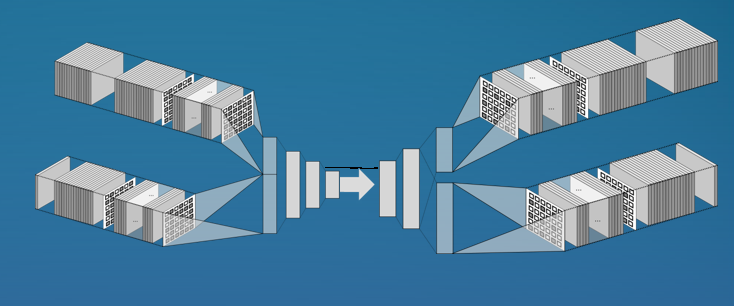

The origin of wind chimes dates back to 1100 BC in Eastern and Southern Asia where the chimes were intended to ward off evil spirits and attract benevolent spirits. Modern wind chimes typically consist of 4 to 8 aluminum tubes with varying lengths and associated resonant frequencies corresponding to a specific musical scale. In addition the wind chimes also include a wind catcher and associated wind clapper to impact the chimes as illustrated in Figure 1 below:

The present paper addresses the underlying physics of wind chimes from the viewpoint of a structural acoustician. The impact excitation and vibration of the structure is addressed including the effects of the surrounding air on the vibration characteristics of the wind chime which is modeled as a sum of cylindrical pipes or beams. The directional characteristics of the transient acoustic field are then addressed.

The dominant sound producing features for each cylindrical pipe/beam are simply described as a sum of temporally decaying modal beam vibrations with different resonant frequencies which are inversely related to the square of the length of the pipe. A simple illustration of the predominant sound producing lowest frequency modal vibration is illustrated in the accompanying video:

The video simply illustrates the lowest modal vibration of a free free beam which is presented as a simple model of a cylindrical wind chime vis-à-vis a cylindrical shell model. The ends of the beam/pipe undergo the maximum transverse deflection and vibration whereas two nodal points with zero deflection are also apparent for the fundamental modal vibration. In contrast to stringed musical instruments, the higher order modal vibrations are associated with a nonharmonic series of resonant frequencies with an increasing number of nodal points as the modal number increases. Experimental results confirm the validity and usefulness of the cylindrical beam model of the wind chime pipes.

Acoustic transient radiation from a vibrating chime is addressed in the paper using a space-time superposition of ring sources along the axis of the chime. The ring sources are shown to result in a space-time varying force on the air in contact with the chime. Furthermore, the force is simply related to the previously noted sum of temporally decaying modal beam vibrations. The directional properties of the acoustic field are discussed and it is shown that the field exhibits nulls in the directions along and perpendicular to the axis of the chime.