1pEAa5 – A study on a friendly automobile klaxon production with rhythm

SangHwi Jee- slayernights@ssu.ac.kr

Myungsook Kim

Myungjin Bae

Sori Sound Engineering Lab

Soongsil University

369 Sangdo-Ro, Dongjak-Gu, Seoul, Seoul Capital Area 156-743

Republic of Korea

Popular version of paper 1pEAa5, “A study on a friendly automobile klaxon production with rhythm”

Presented Monday, December 04, 2:00-2:15 PM, Balcony N

174th ASA meeting, New Orleans

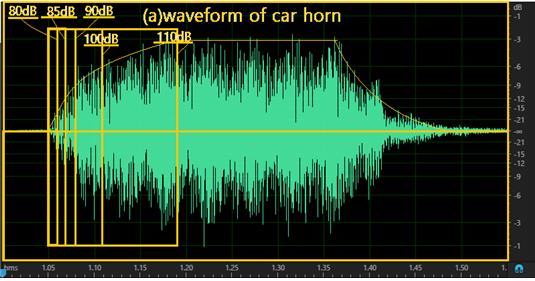

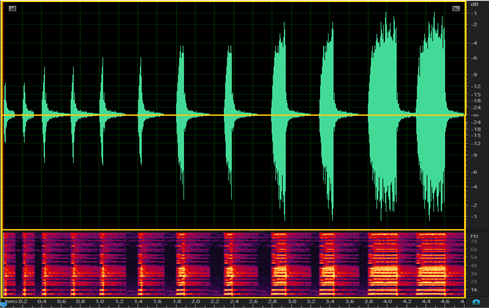

Cars are part of our everyday lives and as a result, traffic noise is always present when we are driving, riding as a passenger or walking down the street. Among the traffic noise, blaring car horns are among the most stressful and unpleasant sounds. Impulse noises, like those experienced from honking traffic horns can lead to emotional dysregulation or emotional hyperactivity of the driver and potentially cause an accident. While impulse sounds may be dangerous, the risk of avoiding car horn use altogether can be just as deadly. Not using horn sounds prevent us from informing pedestrians or other drivers of a potential accident. Although it is an important means of informing the pedestrians and other drivers of a present crisis, until now, car horn sounds and their impact on the listener have not been heavily studied. Generally, the Klaxon electromechanical car horn is a simple mechanical structure, which is excellent in durability and ease of use. However, once it is attached, it can’t change the tone of the horn sound or redesign the sound pressure size. Therefore, in this study, the width of power supply time of Klaxon was adjusted to 5 (0.01s, 0.02s, 0.03s, 0.06s, 0.13s). Then, the sound level of the Klaxon sound was set to 5 sound levels (80dB, 85dB, 90dB, 100dB, 110dB). The experimental result shows that the maximum sound pressure (pmax = 110dB) after operating the Klaxon is tmax.

Equation 1: Ps (dB) = 110 (dB) – {10log (ton / (ton + toff)) + 20log (ton / tmax)

In Equation 1, preferences were evaluated for five types of 5-second Klaxonsounds, which were designed with the Klaxon’s operating time and downtime appropriately adjusted. We performed 100 Mean Option Score (MOS) evaluations of the 5 types of Klaxons three times, then MOS evaluation, and started to listen to the existing Klaxon sounds of three times for 1 second to get the sound criterion. The evaluation items were MOS measurement for risk perception, loudness, unpleasantness, and stress. Results from the evaluation of preference, when designing various forms of the Klaxon sound, noted that giving the horn sound rhythm was preferred compared to the conventional horn sound when continuously heard for 5 seconds. When the rhythm was changed by the sound of Klaxon, the average perceived horn sound level decreased by 20dB. This can be heard in the human ear if the sound is rhythmic rather than normal. Hearing can be perceived as a simple tone, but rhythmic sound can also be perceived easily. In fact, it was found that the sound that when rhythm was added to a sound, it was found to be more pleasant than the corresponding normal sound